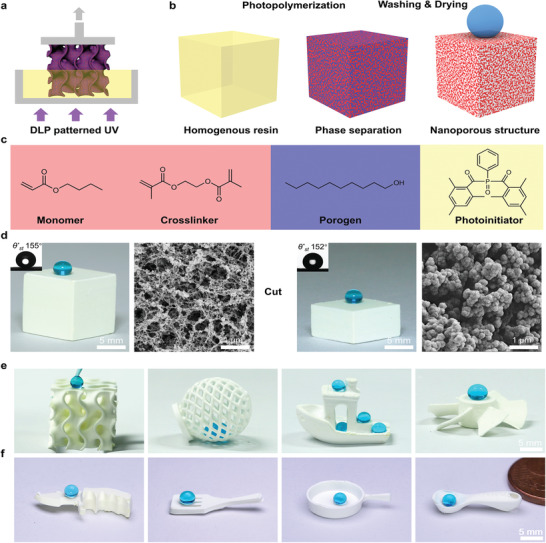

Figure 1.

3D printing of superhydrophobic objects with bulk nanostructure. a) Schematic showing the DLP 3D‐printing process using a phase‐separating ink. b) In this process, photopolymerization induces phase separation of the homogenous ink and generates the inherent nanoporous structures leading to bulk superhydrophobicity. c) Chemical structures of the components of an exemplary ink: BA as the monomer (30 wt%), EDMA as the crosslinker (20 wt%), 1‐decanol as the porogen (50 wt%), and Irgacure 819 as the photoinitiator (2 wt% relative to reactive monomers). d) Photographs of dyed water droplets on the surface (left panel) and cross‐section (right) of a cube printed using the phase separating ink, with the insert showing the measured static water contact angle (θ* st). The nanoporous structure of the cube is shown in the corresponding scanning electron microscopy (SEM) images. e) Complex‐shaped superhydrophobic objects printed using the novel ink demonstrating the design flexibility. f) A superhydrophobic miniaturized kitchen set (knife, spatula, pan and spoon) printed using the ink.