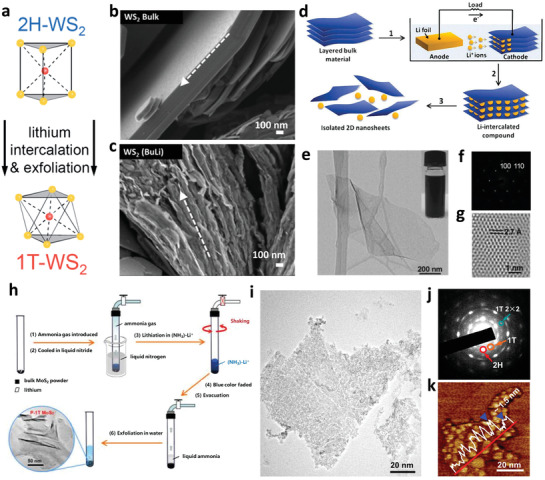

Figure 3.

Three commonly used lithium‐insertion methods to obtain layered TMDs materials NSs. a) Exfoliating the bulk WS2 with organolithium compounds to produce 1T WS2 NSs. Reproduced with permission.[ 33 ] Copyright 2014, Royal Society of Chemistry. b) The SEM images for the bulk WS2 and c) after the BuLi treatment with subsequent exfoliation in water. b,c) Reproduced with permission.[ 89 ] Copyright 2014, American Chemical Society. d) Fabrication of 2D NSs from the layered bulk material with electrochemical lithiation process. e) TEM image of an exfoliated MoS2 NS. Digital photograph of the MoS2 NSs solution is demonstrated as the inset image. f) Selected‐area electron diffraction (SAED) of monolayer MoS2 NS. g) HRTEM image for the exfoliated monolayer MoS2 NS. d–g) Reproduced with permission.[ 90 ] Copyright 2011, Wiley‐VCH. h) A diagrammatic drawing of LAAL processes. i) Morphology of mesoporous 1T MoS2 NSs. j) The corresponding SAED pattern and k) atomic force microscopy (AFM) image of exfoliated MoS2 NSs. h–k) Reproduced with permission.[ 20 ] Copyright 2016, American Chemical Society.