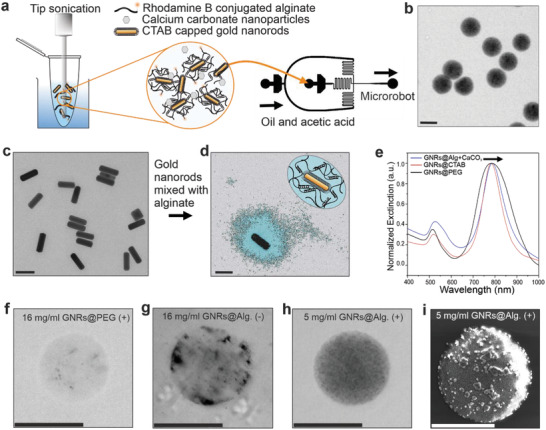

Figure 2.

TACSI microrobot fabrication and characterization. a) Microrobots are produced via microfluidic encapsulation. A mixture of CTAB‐capped GNRs (GNRs@CTAB) and uncrosslinked alginate is subjected to tip sonication prior to microfluidics. Microrobots are fabricated by flowing the pre‐polymer mixture against the oil and acetic acid phase using a two‐channel device. b) An exemplary brightfield image of a group of TACSI microrobots is shown. Scale bar: 30 µm. c) A selected TEM image of GNRs@CTAB is provided. Scale bar: 100 nm. d) Colored TEM image of a single CTAB‐capped GNR, encapsulated in alginate with calcium (GNR@Alg.+CaCO3), showing a layer of polymer around the nanorod is provided, with a schematic representation of the hydrogel coating. Scale bar: 100 nm. e) UV–vis spectra of different GNRs with their normalized extinction maxima at 785 nm, black arrow indicates a shift of 5 nm for the GNRs@Alg.+CaCO3. Exemplary brightfield images of single microrobots fabricated at f) 16 mg ml−1 PEG‐capped GNRs (GNRs@PEG) with tip sonication (+), g) 16 mg ml−1 of GNRs@CTAB without tip sonication (‐), h) 5 mg ml−1 of GNRs@Alg.+CaCO3 with tip sonication (+). Scale bars: 15 µm. i) SEM image of a microrobot, fabricated with 5 mg ml−1 of GNRs@Alg.+CaCO3 (+). The micron sized clusters on the microrobot belong to the sputtered gold layer prior to imaging. Scale bar: 15 µm.