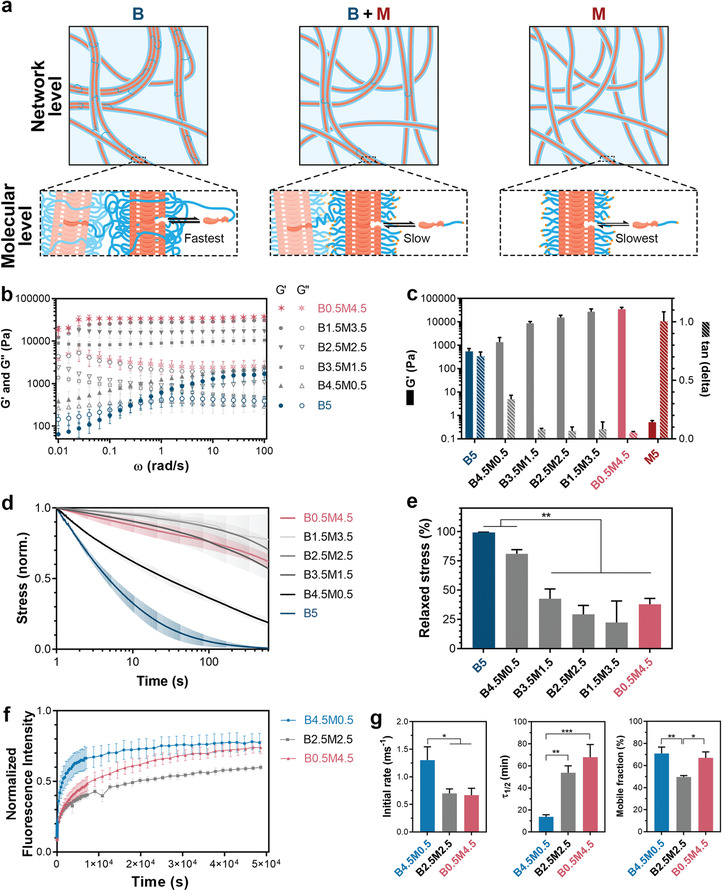

Figure 2.

Hydrogels formulated from different ratios of supramolecular building blocks. a) Schematic illustration of different supramolecular formulations at network and molecular levels. Blue linkages between fibers at network level indicate interfiber cross‐links formed by B‐type molecules, and labels of black arrows at molecular level indicate the rate of molecular exchange dynamics for different formulations. b) Frequency dependence of storage (G′) and loss (G″) moduli of different compositions of supramolecular hydrogels. c) G′ and damping factor (tan(delta)) values of hydrogels measured at 1 rad s−1 and 1% strain. d) Stress relaxation behavior of supramolecular hydrogels measured by subjecting the hydrogels to 1% strain. e) Quantification of stress relaxation in hydrogels after 10 min. f) Fluorescence recovery after photo‐bleaching (FRAP) tests performed on hydrogels containing 20 µm of UPy‐Cy5 supramolecular additives. g) Quantified FRAP results showing the rate of fluorescence recovery during the first 60 s after photo‐bleaching (Initial rate), the timespan during which the Cy5 fluorescence intensity recovers to half its mobile fraction (τ1/2), and the fraction of fluorescence intensity that recovers when fluorescence intensity curves reach plateau values (Mobile fraction). b–g) All hydrogels contained a total polymer content of 5 wt%, and all measurements were performed at 37 °C. All data are shown for n = 3 independent tests per group, and as mean ± s.d. e,g) *, p < 0.05; **, p < 0.01; ***, p ≤ 0.001; one‐way analysis of variance (ANOVA) followed by Bonferroni post hoc.