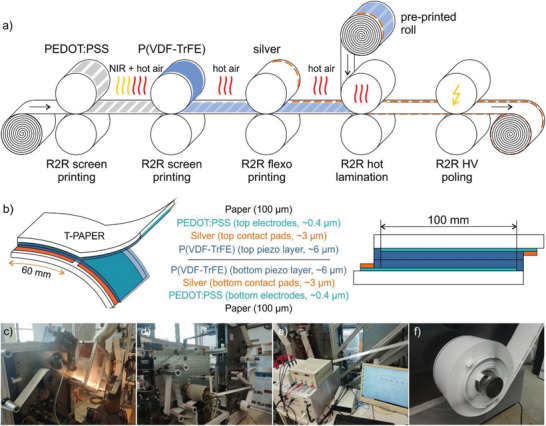

Figure 1.

R2R manufacturing process of T‐PAPER. a) Schematic illustration of R2R printing steps, lamination and inline polarization. b) 3D schema and cross‐sectional view of the T‐PAPER device set‐up (active area per cell 60 × 100 mm2). c) R2R printing press LaborMAN 2, rotary screen printing of PEDOT:PSS electrodes. d) R2R hot lamination of two pre‐printed T‐PAPER rolls at LaborMAN 1 and e) HV inline polarization of laminated T‐PAPER roll at LaborMAN 2. f) Final 260 m T‐PAPER roll.