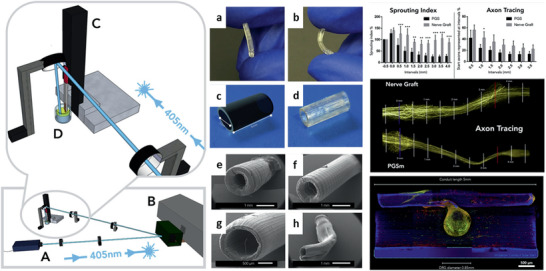

Figure 11.

Computer‐aided model (Google Sketchup) of the micro‐SLA set‐up by Singh et al. for the production of NGCs. The setup consists of a 405 nm laser [A], a DMD [B], a motorized Z‐table [C] and a container with liquid polymer [D]. a,b) The elastic properties of the mAcr‐PGS NGCs. c) A CAD model (Maya, Autodesk) of an ideal 3D printed NGC. d) A final 3D‐printed and finished product of the NGC, ready for implantation. Scanning electron microscope images show the z‐translation speed of 0.03 mm s‐1 and various laser powers of e) 80 mW, f) 65 mW, g) 30 mW and h) 10 mW. Reproduced under the terms of the CC‐BY 4.0 license.[ 162 ] Copyright 2018, the Authors. Published by Elsevier.