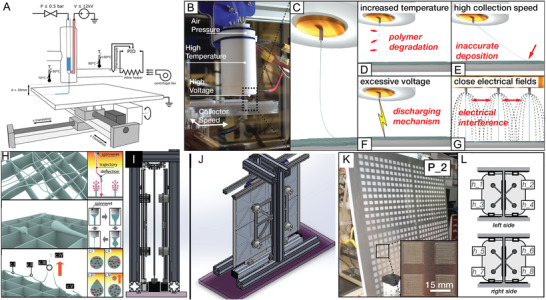

Figure 8.

Overview of MEW printers. A) Schematic illustration of a MEW printer using an industrial heat gun as hot air stream supply, heating the polymer melt while the jet remains in ambient temperature conditions. B) Images of typical single material MEW head and C) the resulting polymer jet. There are limitations during fiber generation resulting from D) polymer degradation due to high temperatures, E) high printing speeds resulting in inaccurate fiber deposition, F) excessive voltage causing arcing, and G) electrical interference between close electrical fields. H) Schematic of fiber printing defects as increased build height due to electrostatic repulsion and/or attraction of the polymer melt, fiber pulsing, or fiber attraction toward the nozzle. I–J) CAD models showing different views of the high‐throughput MEW printer using eight simultaneous printheads extruding onto a vertical collector. K) Images of one side of the vertical collector with 576 scaffolds and L) the labeling of the eight printheads on both, the left and right side. A) Reproduced with permission.[ 21 ] Copyright 2018, Elsevier Ltd. All rights reserved. B–G) Reproduced with permission.[ 44 ] Copyright 2019, Mary Ann Liebert, Inc., publishers. H) Reproduced with permission.[ 50 ] Copyright 2018, Wiley‐VCH GmbH. I–L) Reproduced with permission.[ 44 ] Copyright 2019, Mary Ann Liebert, Inc.