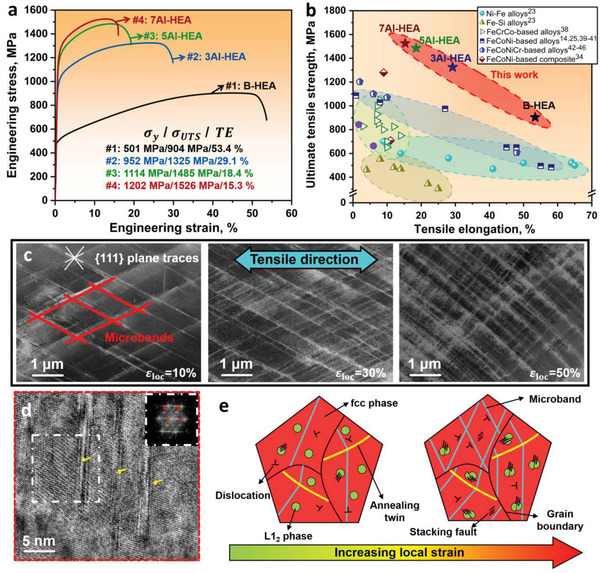

Figure 2.

Mechanical behavior and deformation mechanisms of the 7Al‐HEA. a) Room temperature tensile stress–strain curves for the B‐HEA, 3Al‐HEA, 5Al‐HEA, and 7Al‐HEA. σy, σUTS, and TE represent the yield strength, the ultimate tensile strength and the tensile elongation, respectively. b) σUTS–TE profiles of various classes of soft magnetic materials,[ 14 , 23 , 25 , 34 , 38 – 46 ] including the newly developed soft magnetic HEAs investigated in this work. c) Electron channeling contrast imaging analysis revealing the evolution of the substructure in the 7Al‐HEA with increasing local strain during tensile deformation; the distance between the parallel microbands decreases with increasing local strain. d) HRTEM image of a region at εloc= 50% showing that the L12 nanoprecipitates have been sheared by nano‐spaced stacking faults (SFs); the inserted FFT pattern confirms the ordered structure of the nanoprecipitates in the fcc matrix. e) Schematic illustration of the micro‐processes in the precipitate‐containing HEAs during plastic straining.