Table 1.

Removal of antibiotics with agro-industrial wastes.

| Pharmaceutical Drug | Chemical Structure | Ci (mg/L) | Agro-Industrial Waste | Agro-Industrial Waste Treatment | Biosorbent Concentration (g/L) | Time (h) | Removal Percentage | qmax (mg/g) Langmuir Model |

Reference | DMRR (mg/g·h) |

|---|---|---|---|---|---|---|---|---|---|---|

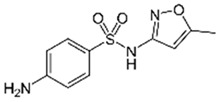

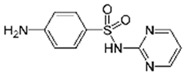

| Sulfamethoxazole |

|

1 | Miscanthus x giganteus biochar | Air-dried, cut, pyrolyzed at 360 °C. | 2.0 | 4 | 32 | - | [211] | 0.3 |

| 3.8 | Rice husk | Rice husks were washed, dried at 60 °C for 48 h, grounded, sieved and pyrolyzed at 500 °C (RH-500) and 800 °C (RH-800) for 2 h. RH-800 was activated with NaOH, heated at 800 °C. | 0.2 | 0.25 | - | - | [212] | - | ||

| 10–60 | Sugarcane bagasse | Untreated sugarcane bagasse was used as an adsorbent, was washed with ultrapure water, dried at 60 °C for 8 h, ground, and triturated. | 0.02 | 0.083 | 51 | 1.43 | [213] | - | ||

| 20 | Wheat straw ashes | The acidification of ashes was performed using 2 M HCl, mixture at 70 °C, filtered, dried at 105 °C. | 1 | 0.5 | 22 | - | [214] | 8.8 | ||

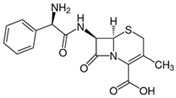

| Sulfamethoxazole |

|

100 | Activated biochar of forage bermudagrass | Dried and sieved, pyrolyzed at 300 °C, activated with NaOH, washed with 3 M HCl and deionized water, dried at 105 °C. | 0.01 | 72 | 91.86 | 424.66 | [215] | 127.6 |

| 0.5–40 | Activated carbon of walnut shell | Pyrolyzed at 300 °C, impregnated with K2CO3, heated at 105 °C and 900 °C. | 0.01 | 48 | - | 93.5 | [216] | - | ||

| 250 | Biochar of malt rootlets | Dried at 50 °C, sieved, heated at 900 °C. | 0.09 | 1.5 | 94 | - | [207] | 1740.7 | ||

| 10 | Biochar of bagasse | Pyrolyzed at 300, 400, and 600 °C, washed with deionized water, dried, crushed, and sieved. | 0.1 | 24 | 41.55 | 54.38 | [217] | 1.8 | ||

| 30 | Almond shell activated biochar | Pyrolyzed at 700 °C and mixed with H2O2. | 0.005 | 3 | 96.88 | 344.8 | [206] | 1940.0 | ||

| 0.5–50 | Bamboo biochar | Cut into 0.6–2 mm size particles, pyrolyzed at 380 °C, cooled, grinded, washed, and dried. Added H3PO4 at 50 °C, heated to 600 °C, cooled, washed with distilled water, and dryed at 120 °C. | 0.1 | 24 | - | 34.01 | [218] | - | ||

| 0.00005 | Pelletized pine forestry waste biochar | Pyrolyzed at 850 °C, ground and sieved, dried at 105 °C. | 40 | 1 | 75 | - | [219] | 0.0000009 | ||

| 0–80 | Arundo donax stems biochar | Pyrolyzed at 300–600 °C, milled, washed with deionized water, and other portion was pulverized for demineralization with HCl and HCL-HF and heated to 750 °C. | 0.1 | 48 | - | 0.473–0.778 * | [220] | - | ||

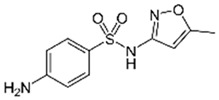

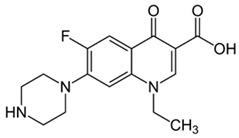

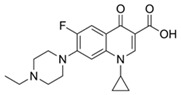

| Ciprofloxacin |

|

50 | Olive stones | Olive stone waste was cleaned with distilled water, dried at 105 °C; was pulverized, washed, and dried at 105 °C; was carbonized at 450 °C; added KOH and activating at 550, 650, and 750 °C. | 1 | 1.25 | 99 | 294.98 | [221] | 39.6 |

| 25 | Activated biochar of barley bagasse | The barley bagasse was dried at 60–70 °C, crushed, sieved, and heated at 105 and 400 °C; activated biochar of barley bagasse with 2 M of K2CO3, dried and washed with distilled water. | 0.5 | 24 | 82 | 104.9 | [222] | 1.7 | ||

| 5.0 | Rice husk | Rice husks were washed, dried at 60 °C for 48 h, grounded, sieved and pyrolyzed 500 °C (RH-500) and 800 °C (RH-800) for 2 h. RH-800 was activated with NaOH, heated at 800 °C. | 0.2 | 0.25 | - | 584.4 | [212] | - | ||

| 10–60 | Sugarcane bagasse | Untreated sugarcane bagasse was used as an adsorbent, was washed with ultrapure water, dried at 60 °C for 8 h, ground, and triturated. | 5 | 0.083 | 99 | 2.61 | [213] | - | ||

| 250 | Dialium guineense seed waste (DGS) | Washed with distilled water, dried in open air, heated at 105 °C, dried, grinded, and sieved. | 0.1 | 2 | 42.9 | 9.17 | [209] | 536.0 | ||

| Dialium guineense seed waste sodium hydroxide modified form (NH-DGS) | Washed with distilled water, dried in open air, heated at 105 °C, dried, grinded, and sieved. Mixed with NaOH, filtered and washed with deionized water, dried at 80–120 °C. | 61.0 | 120.34 | 762.5 | ||||||

| 60 | Banyan aerial roots | Cut 1 cm, washed with deionized water, dried at 80 °C, mixed with 1 M C6H8O7, and heated at 150 °C. | 0.03 | 48 | 90.66 | 65.70 | [223] | 37.8 | ||

| 20 | Biochar of rice straw | Washed, dried at 80 °C, crushed, heated to 700 °C, washed with deionized water. | 1.6 | 24 | 55.0 | 48.80 | [224] | 0.3 | ||

| 100 | Carbon from date palm leaflets | Cut, carbonized with sulfuric acid, heated at 160 °C. | 0.4 | 48 | - | 133.3 | [225] | - | ||

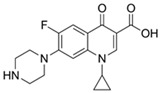

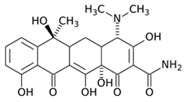

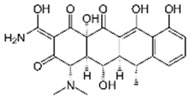

| Tetracycline |

|

100 | Alfalfa biochar | Pyrolyzed at 500 °C, washed with deionized water and filtered (0.45 µm), and washed with 0.1 M HCl. | 0.01 | 48 | - | 372.31 | [226] | - |

| Bermudagrass biochar | - | 44.24 | - | |||||||

| 10 | Activated carbon from peach stones (AC-PS) | Washed with ultrapure water, dried at 110 °C, and chemically activated with H3PO4. | 0.8 | 3 | 96.1 | 845.9 | [227] | 4.0 | ||

| 100 | Activated carbon of hard Shell of apricot stone | Washed with distilled water, ground, added H3PO4, heated to 100 °C and after to 400 °C, washed with distilled water, dried at 80 °C. | 0.3 | 24 | 100 | 308.33 | [228] | 13.9 | ||

| 20 | Activated nanobiochar from vine wood | Washed, pyrolyzed at 600 °C, activated with NaOH 5% w/w and NaCl (3 M). | 0.4 | 8 | 88.17 | 1.98 | [201] | 5.5 | ||

| 100 | Spent black tea leaves (SBTL) | Steep under stirring with boiling water 100 °C, filtered, washed with distilled water, dried at 100 °C, ground. | 0.2 | 3 | 78 | - | [229] | 130.0 | ||

| Pomegranate peel (PP) | Ground and pulverized, steeped under stirring with boiling water 100 °C, filtered, washed with distilled water, dried at 100 °C, ground. | 0.3 | 0.5 | 90 | - | 600.0 | ||||

| 50 | Bamboo charcoal | Carbonized at 150–250 °C, 250–400 °C and 400–700 °C, ground and sieved, washed, dried at 105 °C. | 1 | 24 | 87.6 | 22.7 | [230] | 1.8 | ||

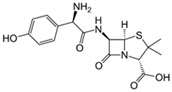

| Amoxicillin |

|

25 | Banana peel activated carbon | Activated carbon by H3PO4, carbonized at 350 °C, 450 and 500 °C. | 1.5 | 2 | 96.02 | 393.70 | [231] | 8.0 |

| 100 | Activated biochar from corn cob | Corn cobs were used for activated biochar with ZnCl2, dried at 120 °C for 12 h, pyrolyzed at 700 °C for 2 h. | 1 | 6 | 65.88 | 175.86 | [232] | 11.0 | ||

| 700 | Bertholletia excelsa capsules | Milled, mixed with ZnCl2, dried at 80 °C, pyrolyzed from 25 up to 600 or 700 °C, cooled, and refluxed with HCl. | 1.5 | 0.5 | 98.60 | 388.4 | [208] | 920.3 | ||

| 25 | Olive stone | Washed with tap water and impregnated with H3PO4 at 100 °C for 9 h, dried at 170 °C and 380 °C, washed with distilled water, and dyed at 110 °C. | 1.0 | 100 | 93 | 57.04 | [233] | 0.2 | ||

| 20 | Activated nanobiochar from vine wood | Washed, pyrolyzed at 600 °C, activated with NaOH 5% w/w and NaCl (3 M). | 0.4 | 8 | 60.23 | 2.69 | [201] | 3.8 | ||

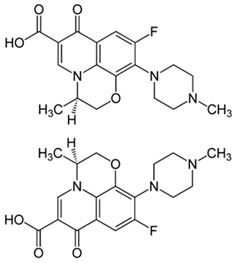

| Norfloxacin |

|

15–150 | Activated carbons of red mombin seeds | The red mombin seeds, corn cob, coffee husk, internal and external parts of mango seeds and ice cream beans were washed with potable water and dried at 80 °C, were grounded and sieved, all raw materials were mixed with ZnCl2 and were pyrolyzed at 600 °C for 2 h. | 0.01 | 7 | - | 404 | [202] | - |

| Activated carbons of corn cob | - | 264 | - | |||||||

| Activated carbons of coffee husk | - | 235 | - | |||||||

| Activated carbons of internal parts of mango seeds | - | 221 | - | |||||||

| Activated carbons of external parts of mango seeds | - | 262 | - | |||||||

| Activated carbons of ice cream beans | - | 84 | - | |||||||

| 5 | Rice husk | Washed with distilled water, dried at 60 °C for 48 h, ground to powder and sieved. | 0.2 | 3 | 59.51 | - | [234] | 5.0 | ||

| Coffee husk | 70.83 | - | 5.8 | |||||||

| 10 | Biochar from potato stem | Washed, dried at 80 °C, chopped, crushed, sieved, pyrolyzed at 500 °C. | 0.1 | 36 | - | 5.24 | [235] | - | ||

| Ofloxacin |

|

25–250 | Activated carbons of red mombin seeds | The red mombin seeds, corn cob, coffee husk, internal and external parts of mango seeds and ice cream beans were washed with potable water and dried at 80 °C, were grounded and sieved, all raw materials were mixed with ZnCl2 and were pyrolyzed at 600 °C for 2 h. | 0.01 | 7 | - | 380 | [202] | - |

| Activated carbons of corn cob | - | 267 | - | |||||||

| Activated carbons of coffee husk | - | 202 | - | |||||||

| Activated carbons of internal parts of mango seeds | - | 176 | - | |||||||

| Activated carbons of external parts of mango seeds | - | 254 | - | |||||||

| Activated carbons of ice cream beans | - | 77 | - | |||||||

| 100 | Bamboo sawdust biochar | Pyrolyzed at 500 °C, washed with distilled water, dried at 105 °C. | 0.05 | 96 | - | 45.11 | [236] | - | ||

| 50 | Moringa oleifera pod husks (AMOP) | Air-dried, pulverized, sieved, activated with NH4Cl, filtered, washed with distilled water, and air-dried. | 2.5 | 4 | 90.98 | 3.597 | [237] | 4.5 | ||

| Biochar of Moringa oleifera pod husks (CMOP) | Air-dried, pulverized, sieved, activated with NH4Cl, filtered, washed with distilled water, air-dried, pyrolyzed at 350 °C, washed with distilled water, air-dried. | 99.84 | 5.051 | 5.0 | ||||||

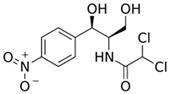

| Chloramphenicol |

|

5–100 | Wheat straw | Pyrolyzed at 550 °C and 700 °C, respectively, crushed and sieved, washed with HCl and deionized water. | 0.05 | 24 | - | 11.3 | [238] | - |

| Softwood | - | 8.8 | - | |||||||

| 50 | Bamboo charcoal | Carbonized at 150–250 °C, 250–400 °C and 400–700 °C, ground and sieved, washed, dried at 105 °C. | 1.0 | 24 | 70.3 | 8.1 | [230] | 1.5 | ||

| Doxycycline |

|

20 | Biochar of rice straw | Washed, dried at 80 °C, crushed, heated to 700 °C, washed with deionized water. | 1.6 | 24 | 90.0 | 170.36 | [224] | 0.5 |

| 100 | Spent black tea leaves (SBTL) | Steep under stirring with boiling water 100 °C, filtered, washed with distilled water, dried at 100 °C, ground. | 0.05 | 2.5 | 89 | - | [229] | 672.0 | ||

| Pomegranate peel (PP) | Ground and pulverized steep under stirring with boiling water 100 °C, filtered, washed with distilled water, dried at 100 °C, ground. | 0.15 | 1.5 | 83 | - | 368.9 | ||||

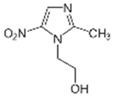

| Metronidazole |

|

100 | Cassava starch waste | Dried at 60 °C, activated with H3PO4, NaOH and combination of both, heated at 105 °C, washed with water, dried at 105 °C, pyrolyzed at 900 °C. | 0.1 | 24 | 55 | - | [239] | 22.9 |

| 0.5–40 | Activated carbon of walnut Shell | Pyrolyzed at 300 °C, impregnated with K2CO3, heated at 105 °C and 900 °C. | 0.01 | 48 | - | 93.5 | [216] | - | ||

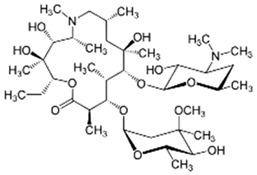

| Azithromycin |

|

200 | Biochar from Terminalla chebula (CBC) | Cleaned, dried, and peeled the bagasse was shredded, washed, dried 72 h at 70 °C, heated for pyrolysis at 500 °C for 1 h; after cooling, washed and dried at 70 °C for 12 h. | 200 | 2 | 57.17 | 21.36 | [240] | 0.29 |

| Biochar from sugarcane bagasse (BBC) | 60.03 | 17.95 | 0.30 | |||||||

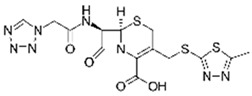

| Cefazolin |

|

30 | Alperujo | Alperujo dried were covered with distilled water, heated at 160–220 °C, dried at 50 °C, and sieved. | 0.125 | 24 | - | 1572.73 | [241] | - |

| Sulfadiazine |

|

20 | Activated carbons from olive pomace | Washed with hot distilled water, dried at 103 °C, ground and sieved, pyrolyzed at 450 °C, impregnated with KOH, stirred at 60 °C, dried at 103 °C. The mixture was activated at 560, 700, and 840 °C, cooled, washed with distilled water, and dried at 103 °C. | 0.8 | 2 | 99 | 66.2 | [242] | 12.3 |

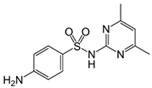

| Sulfamethazine |

|

0.5–50 | Bamboo biochar | Cut into 0.6–2 mm size particles, pyrolyzed at 380 °C, cooled, grinded, washed, and dried. Adding H3PO4 at heated 50 °C and heated at 600 °C, cooled, washed with distilled water and drying at 120 °C. | 0.1 | 24 | - | 40.11 | [218] | - |

| Enrofloxacin |

|

100 | Bamboo sawdust biochar | Pyrolyzed at 500 °C, washed with distilled water, dried at 105 °C. | 0.05 | 96 | - | 45.88 | [236] | - |

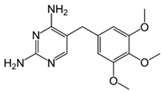

| Trimethoprim |

|

29 | Charcoal from feathers | Washed, drying at 80 °C, crushed, heated at 600 °C, dried 105 °C, sieved to 100–160 mesh. | 0.2 | 60 | 90 | 164 | [243] | 2.2 |

| Cephalexin |

|

20 | Activated nanobiochar from vine wood | Washed, pyrolyzed at 600 °C and activated with NaOH 5% w/w and NaCl (3 M). | 0.4 | 8 | 76.02 | 7.08 | [201] | 4.8 |

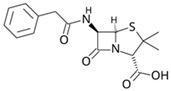

| Penicillin G |

|

20 | Activated nanobiochar from vine wood | Washed, pyrolyzed at 600 °C and activated with NaOH 5% w/w and NaCl (3 M). | 0.4 | 8 | 73.94 | 8.41 | [201] | 4.6 |

Ci = initial concentration; qmax = maximum absorption according to the adsorption isotherm model Langmuir/Freundlich; DMRR = drug mass removal rate, calculated in this review; * adsorption isotherm model: Freundlich.