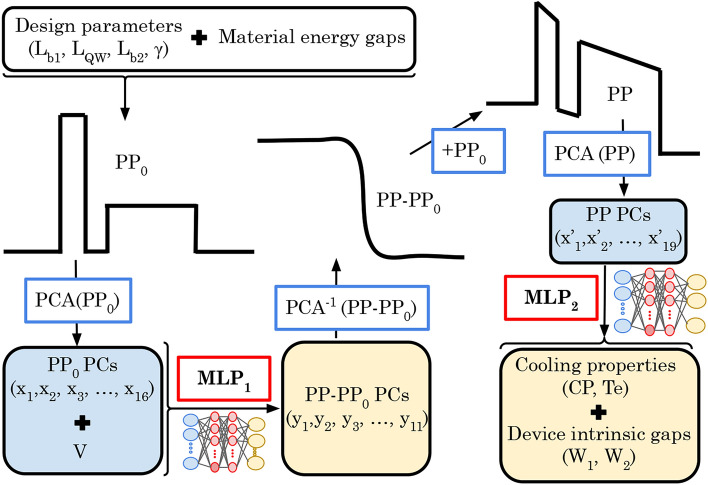

Fig. 2.

Machine learning procedure. From the combination of the design parameters ( ) and the material energy gaps, the first solution of the potential profile (

) and the material energy gaps, the first solution of the potential profile ( ) is constructed, and its features are reduced by applying the principal component analysis (PCA(PP0)) to obtain the

) is constructed, and its features are reduced by applying the principal component analysis (PCA(PP0)) to obtain the  principal components (

principal components ( ). The

). The

combined with the V are the inputs of the first multi-layer perceptron (MLP1), which gives the difference between potential profile (PP) and

combined with the V are the inputs of the first multi-layer perceptron (MLP1), which gives the difference between potential profile (PP) and  (PP-PP0)

(PP-PP0)  as the output. The PP of the device is obtained by applying the inverse principal component analysis (PCA) (

as the output. The PP of the device is obtained by applying the inverse principal component analysis (PCA) ( (PP-PP0) and adding the PP0. The inputs of the second multi-layer perceptron (MLP2) are the PP

(PP-PP0) and adding the PP0. The inputs of the second multi-layer perceptron (MLP2) are the PP  obtained from the application of PCA(PP) to the PP. Finally, the MLP2 provides, as output the information about the cooling properties (CP,

obtained from the application of PCA(PP) to the PP. Finally, the MLP2 provides, as output the information about the cooling properties (CP,  ) and the device activation energies (

) and the device activation energies ( ,

,  ).

).