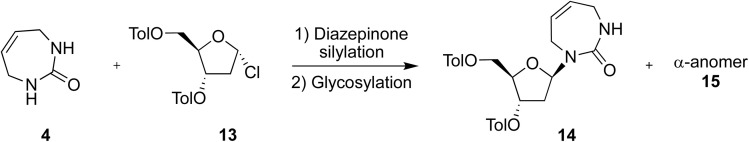

Optimization of direct glycosylation reaction conditions.

| ||||||

|---|---|---|---|---|---|---|

| Entry | Silylation conditions | Solvent/catalyst | Höffer's sugar (eq.) | Temp. (°C) | Anomeric ratio (crude) (β/α)a | Isolated yield (%) (β-anomer) |

| 1 | BSTFA (excess)a acetonitrile | CH2Cl2 | 1.1 | RT | N/A | N/A |

| SnCl4 (1.0 eq.) | ||||||

| 2 | Et3N (1.6 eq.) | ClCH2CH2Cl | 0.85 | −30 | 9 : 1 | 48 |

| TMS-Cl (1.2 eq.) benzene | SnCl4 (3.0 eq.) | |||||

| 3 | Et3N (2.0 eq.) | ClCH2CH2Cl | 0.85 | −30 | 9 : 1 | 51 |

| TMS-Cl (1.4 eq.) benzene | SnCl4 (3.0 eq.) | |||||

| 4 | Et3N (1.6 eq.) TMS-Cl (1.2 eq.) benzene | ClCH2CH2Cl | 1.2 | −30 | 5 : 1 | 28 |

| SnCl4 (3.0 eq.) | ||||||

| 5 | Et3N (1.6 eq.) TMS-Cl (1.2 eq.) benzene | ClCH2CH2Cl | 0.85 | 0 | 10 : 1 | 60 |

| SnCl4 (3.0 eq.) | ||||||

Entry 1 as per Cristalli et al.10

Crude anomeric ratio's measured by H NMR.