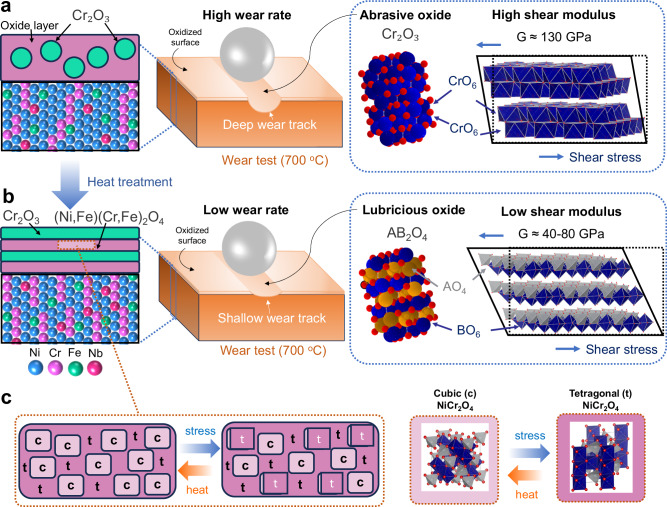

Fig. 6. High-temperature tribological model for Inconel 718.

a, b Schematic representation of the impact of heat treatment on the formation of abrasive corundum (Cr2O3) vs. lubricious spinel (AB2O4) oxides on the surface of Inconel 718 during high-temperature wear. Abrasive oxide layer results in deep wear track and high wear rate (volume loss), while lubricious oxide layer results in shallow wear track and low wear rate. Red atom in oxide structure represents oxygen, blue and yellow atoms represent metal. c Illustration of associated phase transformation in the surface oxide layer of heat-treated Inconel at 700 °C. c and t represent cubic and tetragonal, respectively.