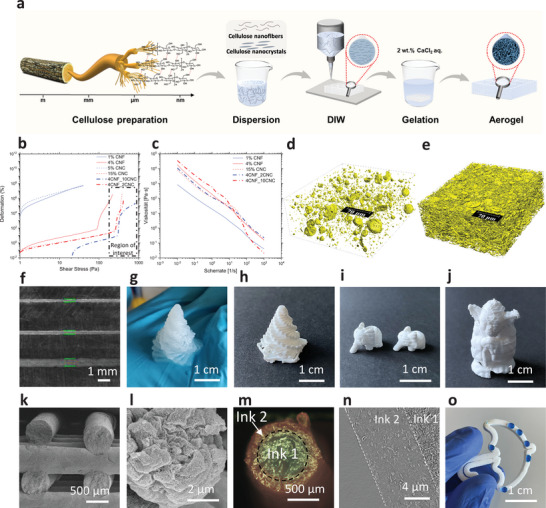

Figure 1.

Additive manufacturing of pure nanocellulose hydrogels and aerogels. a) Process scheme: CNF and CNC extraction from wood pulp, dispersion in water, and concentration adjustment to tune the ink rheology and DIW of the cellulose inks, initiate gelation by immersion in a 2 wt.% CaCl2 solution, post‐processing, and supercritical CO2 drying. b) Amplitude sweep of inks with various CNF and CNC combinations. c) Shear‐thinning behavior. d) 3D volume rendering of a 4CNF_2CNC aerogel and, e) 4CNF_10CNC sample: higher density CNC‐CNF mixed aggregates (yellow, 1.3 vol.% for 4CNF_2CNC and 15.5 vol.% for 4CNF_10CNC) embedded in low‐density matrix (predominantly CNF) (white) (200×200×80 µm3, effective voxel size of 162.5 nm). f) Filaments printed from 250‐µm, 410‐µm, and 840‐µm nozzles. Printed g) hydrogel and h–j) dried gel objects. k) SEM cross‐section of a dried grid structure. l) SEM observation of the mesoporous aggregates. m) Coaxial printing of hydrogels with 4CNF_2CNC shell and 4CNF_2CNC_graphite core. n) Longitudinal µCT cross‐section of the core‐shell filament. o) 3D printed hydrophobic 4CNF_10CNC aerogel, xCNF_yCNC stands for x wt.% CNF and y wt.% CNC in the ink formulation.