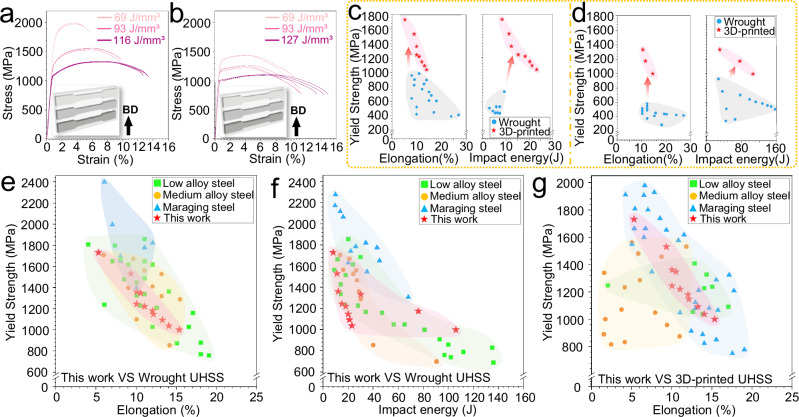

Fig. 4. Mechanical properties.

Typical engineering tensile stress-strain curves of the 3D-printed (a) 1080 steels and (b) 1040 steels at different laser energy inputs, with insets and arrows showing the sample sectioning orientation and building direction (BD), respectively. Ashby plots illustrating mechanical properties of 3D-printed (c) 1080 and (d) 1040 steels in comparison with their conventionally wrought counterparts26–33. Ashby plots comparing mechanical properties of 3D-printed plain carbon steels against typical commercial ultra-high strength steels (UHSS) manufactured by (e, f) wrought and (g) 3D-printing, as reported previously14,27,35–41. The commercialized steels in (e−g) includes 4130, 4140, 4340, 8640, and 300 M as typical low alloy UHSS, H11 and H13 as typical medium alloy UHSS, and 18Ni(200), 18Ni(250) and 18Ni(300) maraging steels. The shaded bands in these Ashby plots show the populated areas, derived from the corresponding data distributions. Note that the data of the 3D-printed plain carbon steels in these Ashby plots were selected from Supplementary Table 3 to effectively illustrate the distribution of the achievable properties while avoiding excessive data overlap. The full data for all properties at different processing conditions is listed in Supplementary Table 3. Source data are provided as a Source Data file.