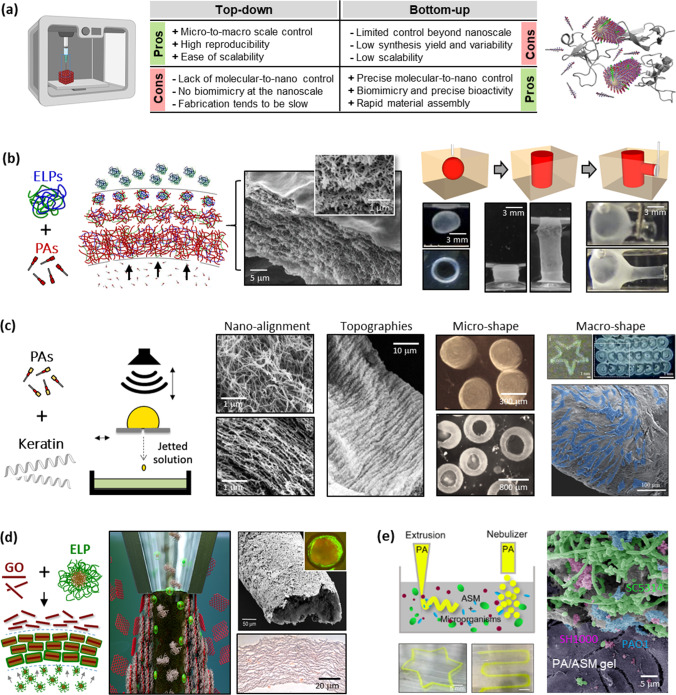

Fig. 5.

Supramolecular biofabrication. a Advantages and disadvantages of merging top-down (e.g., biofabrication) and bottom-up (e.g., supramolecular self-assembly) strategies. Reproduced from Ref. [106], Copyright 2010, with permission from Elsevier. b Through diffusion–reaction mechanisms, the supramolecular assembly of peptide amphiphiles (PAs) and elastin-like proteins (ELPs) gives rise to hierarchical-organised membranes and allows liquid-in-liquid fabrication of dynamic tubular structures. Reproduced from Ref. [99] (Copyright 2015, with permission from Macmillan Publishers Limited) and Ref. [107] (Copyright 2023, with permission from the authors, licensed under CC BY 4.0). c Drop-on-demand printing, with its involved hydrodynamic forces, is exploited to create PA-keratin composites with dictated fibre nano-alignment, surface topography, and macroscopic geometries. Reproduced from Ref. [102], Copyright 2018, with permission from WILEY-VCH Verlag GmbH & Co. KGaA, Weinheim. d Graphene oxide (GO) flakes co-assembled with ELPs are harnessed to grow and bioprint vascular-like perfusable tubes. Reproduced from Ref. [103] (Copyright 2020, with permission from the authors, licensed under CC BY 4.0) and Ref. [104] (Copyright 2021, with permission from the authors, licensed under CC BY 4.0). e Co-assembly of PAs and artificial sputum enables the creation of printable 3D models of bacterial infection. Reproduced from Ref. [105], Copyright 2023, with permission from the authors, licensed under CC BY 4.0