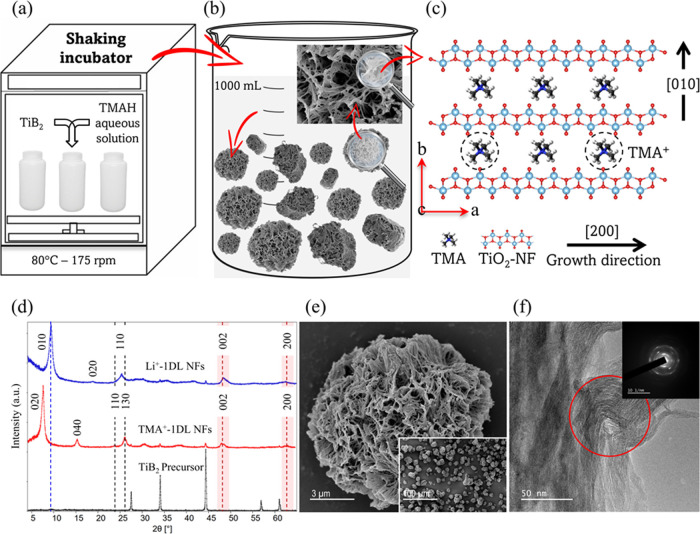

Figure 1.

Processing details and characteristics of 1DL powders obtained by heating a TiB2 precursor in TMAH solution at 80 °C for 5 days. (a) Schematic showing a temperature-controlled shaker used to convert TiB2 powder into 1DL powders and (b) washing protocol followed to remove excess TMAH after the reaction. (c) DFT-generated lepidocrocite titanate structure showing 2 Ti atom-thick ribbons growing and stacking along a- and b-crystallographic directions, respectively. (d) XRD pattern of TiB2 precursor powder (bottom black curve), TiB2-derived 1DLs after the reaction and washing with EtOH (middle red curve), and after treatment in a 5 M LiCl solution (top blue curve). Dashed vertical lines denote peak indices. Vertical red bands denote the 002 and 200 nonbasal reflections of the lepidocrocite titanate structure. (e) Typical SEM micrograph of 1DL porous hierarchical particles after LiCl treatment. Inset is low magnification imaging of free-flowing and nonagglomerating 1DL hierarchical particles. (f) TEM micrograph of 1DL bundle oriented along the fiber axis. The inset shows the SAD pattern of area bounded by a red circle and is characterized by two sets of arcs.