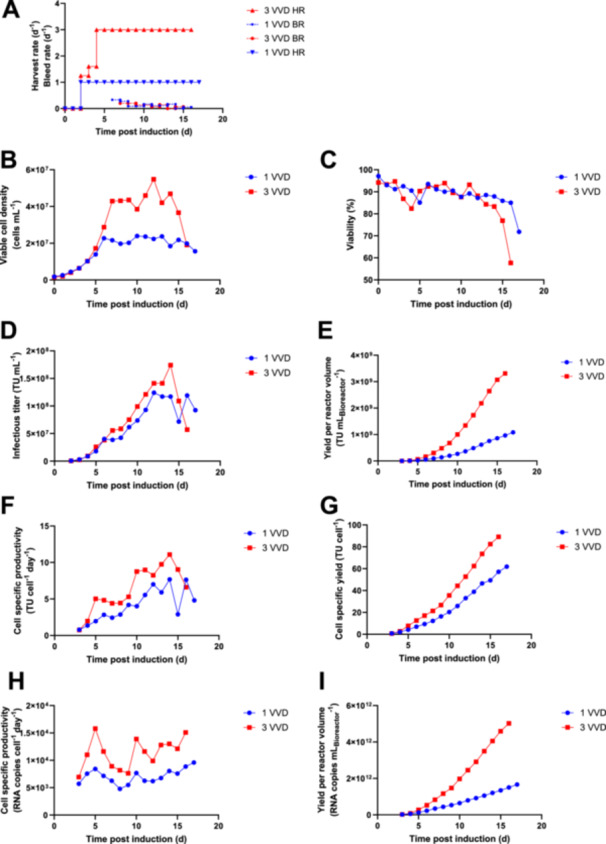

Figure 4.

Bench‐top bioreactor perfusion processes for stable lentivirus production using acoustic wave cell separation with optimized set‐up. The standard process at a harvest rate of 1 VVD was performed in a 5 L bioreactor. The intensified process was performed at a harvest rate of 3 VVD in a 2 L bioreactor. A PharmaPure low spallation pump tubing size 17 was used to recirculate the cell suspension for operation in perfusion mode. The medium was supplemented with 0.5% poloxamer 188 and 0.4% cholesterol lipid concentrate. The run was performed with one vessel per condition. BR = bleed rate, HR = harvest rate, VVD = vessel volumes per day. (A) Harvest rate and bleed rate. (B) Viable cell density. (C) Cell viability. (D) Infectious virus titer. (E) Yield of infectious titer per reactor volume or volumetric yield. (F) Cell‐specific productivity of infectious virus. (G) Cell‐specific infectious virus yield. (H) Cell‐specific productivity of vector RNA genome. (I) Cell‐specific yield of vector RNA genome.