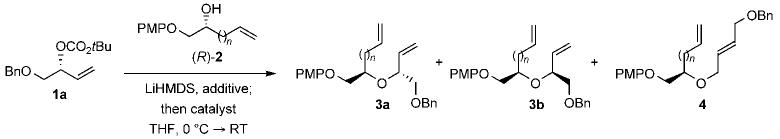

Table 1.

Optimization of the rhodium-catalyzed allylic etherification with the copper(I) alkenyl alkoxide derived from (R)-2 (n=1).[a]

| Entry | Catalyst | Additive | 3/4[b],[c] | d.r.3a/3b[b] | Yield[%][d] |

|---|---|---|---|---|---|

| 1 | [RhCl(PPh3)3]/P(OMe)3 | CuCl | 9:1 | 2:1 | 20 |

| 2 | [RhCl(PPh3)3]/P(OMe)3 | CuI | 11:1 | 4:1 | 63 |

| 3 | [{RhCl(C2H4)2]/P(OMe)3 | CuI | 13:1 | 3:1 | 63 |

| 4 | [RhCl(PPh3)3]/P(OMe)3 | CuI/PPh3 | 13:1 | 7:1 | 46 |

| 5 | [RhCl(PPh3)3]/P(OMe)3 | CuI/P(OMe)3 | 49:1 | ≥99:1 | 72 |

| 6 | [RhCl(PPh3)3] | CuI/P(OMe)3 | 24:1 | 10:1 | 15 |

All reactions (0.25 mmol) were carried out with 10 mol% of the catalyst in tetrahydrofuran with 1.9 equivalents of the copper alkoxide.

Diastereomeric ratios were determined by capillary GLC on aliquots of the crude reaction mixture.

Authentic standards were prepared independently by using copper cyanide as an additive.

Yields of the isolated products. Bn=benzyl, HMDS=hexamethyldisilazide, PMP=p-methoxyphenyl, RT=room temperature.