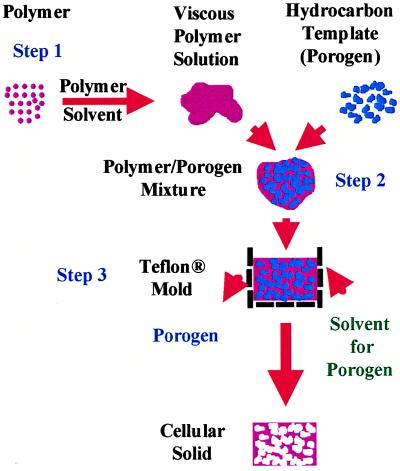

Figure 1.

A schematic representation of the steps involved in the preparation of polymeric foams (the composition details provided as an example yield a foam 1 cm3 in volume with ≈87% porosity). Step 1: The polymer (200 mg) is dissolved in a suitable solvent (e.g., methylene chloride, chloroform) and then mixed with the hydrocarbon porogen (e.g., paraffin, beeswax, bone wax) (800 mg of 300- to 500-μm particles) to yield a moldable mixture. Step 2: This mixture is then compacted in a Teflon mold (1 cm3). Step 3: The polymer/porogen mixture in the mold is then immersed in an aliphatic hydrocarbon solvent (e.g., pentane, hexane), which is a nonsolvent for the polymer, for 20 min at 45–50°C. During this step, the porogen and polymer solvent are extracted with concurrent precipitation of the polymer phase. To improve the efficiency of solvent penetration, the mold is equipped with small (1 mm in diameter) openings on all faces. Residual porogen is removed by repeating the last step three more times. The foam obtained is then dried under vacuum to remove any trace of solvents.