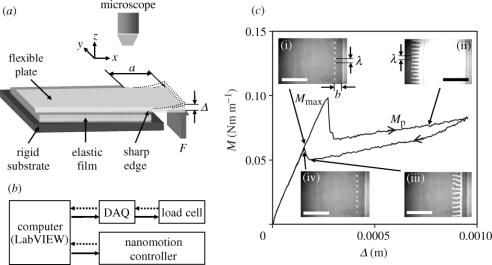

Figure 1.

(a) (b) Schematic of the displacement controlled peel experiment ((a) is reproduced from Ghatak et al. 2004) in which the free edge of a flexible plate adhering to the elastomeric (PDMS) film is delaminated at a constant rate of 5 μm s−1. The elastomeric film bonded to the lower rigid substrate may have either a sharp edge or be decorated with incision (see figure 3). (c) illustrates the moment–displacement (M–Δ) data of a thin silanized glass plate of flexural rigidity 0.05 Nm peeling from a PDMS film (thickness 150 μm, shear modulus 0.9 MPa) having an edge crack. During the delamination cycle, bubbles first nucleate (i) at a distance b inside the sharp edge, followed by their growth and coalescence as reported in Ghatak et al. (2004). At the onset of crack propagation, M reaches its maximum value (Mmax). Once the crack opens up, it propagates (ii) on the smooth adhesive film with a lower M (Mp). The slight upward slope of M is owing to the fact that the energy release rate in this phase is not entirely given by the bent plate, but contributed by the shear deformation of the PDMS film as well. The above sequence can be reversed by decreasing the plate displacement Δ (iiiiv). The degree of the reversibility of the crack opening and closing are illustrated in the M–Δ plots. The scale bars in (c) are 3 mm.