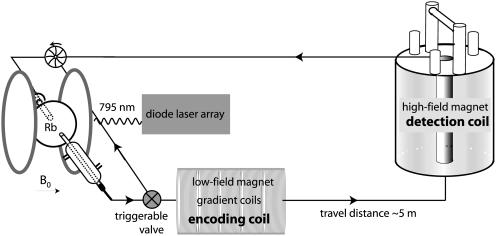

Fig. 2.

A home-built closed-circuit polarizer for laser polarization of 129Xe is illustrated on the left side. Here, a gas mixture ratio of 1:2:3 of [Xe]/[N2]/[He] with a total pressure of 7 atm was used. Polarizer, encoding, and detection sites were connected in a closed loop, maintaining a constant pressure of 7 atm (27). This setup was used only for the remote imaging experiment. Mostly 1/4-inch teflon tubing was used for connecting the loop. Xenon gas with a polarization of 1–2% was produced in a continuous flow mode. A three-way gas flow valve (ASCO) was used to direct the flowing gas either through the magnets or back to the inlet of the polarizer. The return line has an adjustable needle valve restriction so that a constant flow rate (and therefore a constant 129Xe polarization) can be maintained in the pumping cell even during stopped-flow operation, which is necessary to allow sufficient encoding time. The low-field magnet (4–7 mT, 129Xe frequency of 47.3–83.5 kHz) for the encoding site is a home-built solenoid electromagnet (14) with a bore size of 29.8 cm. The pulses are gated and generated from a Hewlett–Packard 3314A frequency generator and amplified to 8 Vp-p by an Amplifier Research (Souderton, PA) 75-W unity gain amplifier for an experimental π/2 time of 48–70 ms. 3D gradient coils are fixed to the wall of the magnet bore. The high-field detection takes place inside a 4.2-T (129Xe frequency of 49.8 MHz) super wide bore magnet equipped with a Chemagnetics–Otysuka Electronics (Fort Collins, CO) spectrometer.