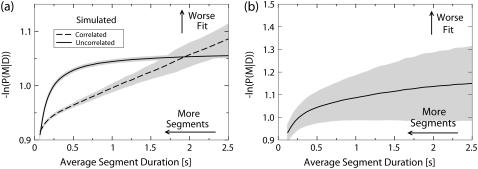

FIGURE 2.

Calibration plots for (a) the simulated data with no underlying motion and (b) flopping beads attached by dynein are shown. The horizontal axis is the average duration of a line segment used to fit the tracking data. The vertical axis is the value of the negative logarithm of the posterior probability scaled by the number of data points. In panel a the dashed line represents the calibration curve for the data simulated using the computer model of a flopping cargo; the solid line represents the calibration curve for data simulated using uncorrelated Gaussian noise as the model of thermal fluctuations. In panel b the solid line represents the calibration curve obtained from the tracks of flopping beads attached by dynein. The calibration curves were obtained by (a) averaging the raw calibration data (not shown) obtained by processing 20 simulated tracks each lasting 20 s, and (b) four tracks with a combined duration of ∼250 s for the flopping beads attached by dynein. The gray areas around the curves represent the uncertainty in the calibration values computed as the standard deviation of the mean of the raw calibration data.