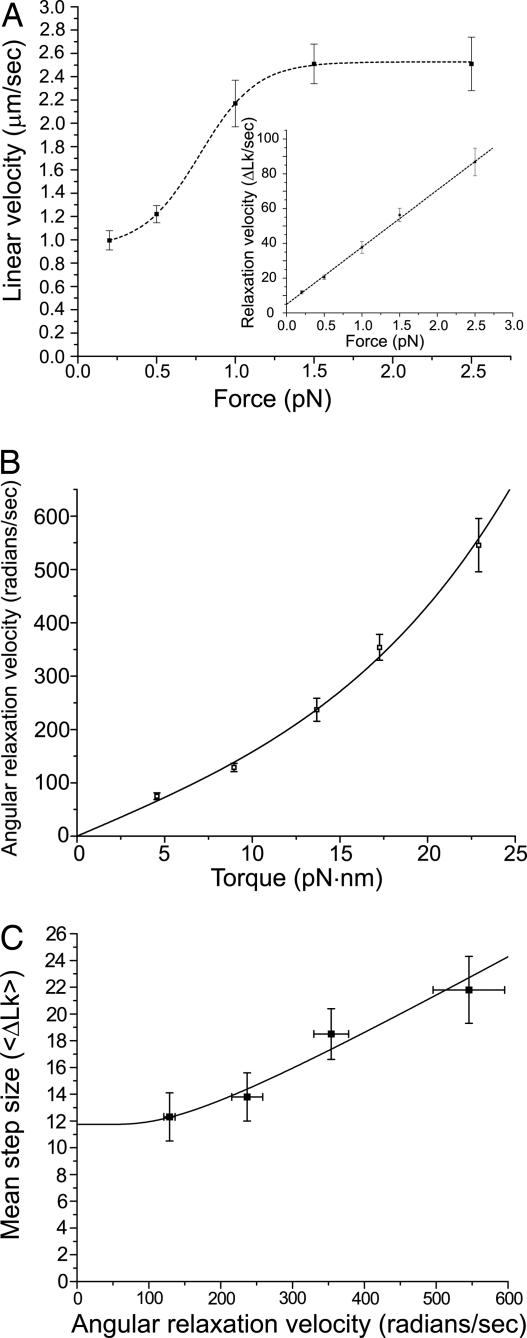

Fig. 4.

Linear and angular velocity dependencies on force and torque. (A) Linear velocity (μm/sec) has a nonlinear dependence on force, indicating that bead translational drag forces do not limit the rate of relaxation. The dashed line serves as a visual guide and does not correspond to a fit. (Inset) Plot of the angular relaxation velocity versus force whose dependence is linear over the range of forces studied. The linear regression fit has a correlation coefficient of 0.991. (B) Angular relaxation velocity ω (rad/sec) initially increases linearly with torque, indicating that rotational friction is the limiting source of friction in the relaxation over the range of forces studied (SI). The line corresponds to a fit of the data to the expression relating angular velocity to torque (SI), with positive and negative angular barrier widths set equal (θ+ = θ−), kBT = 4.1 pN·nm, and ηℓ3 = 10−9 pN·nm·sec. From the fit (reduced χ2 value = 1.4), the energy barrier (EB) is equal to 80.1 ± 0.7 pN·nm or 11.5 ± 0.1 kcal/mol. (C) The mean step size increases with increasing angular relaxation velocity. The line corresponds to a fit of the data to an equation describing the probability per turn that religation does not occur (P1), noting that 〈ΔLk〉 = −1/(1 − P1) (see SI). Using this model, we obtain values of kδ = 361.4 ± 132.4 sec−1 and k′δ = 33.8 ± 6.7 sec−1, respectively, where k and k′ are the cleavage and religation rates and δ is the angular range where cleavage and religation occur. The fit indicates that 〈ΔLk〉 = 11.7 ± 1.0 at zero angular velocity. In all cases, the error bars represent the standard error.