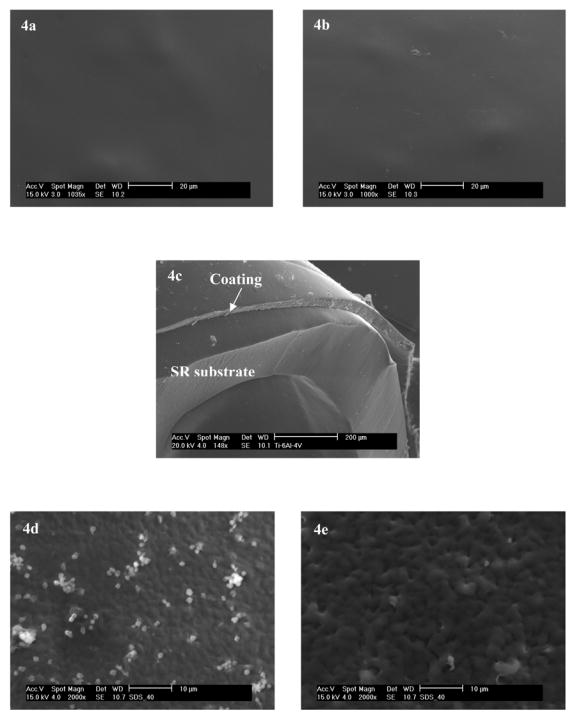

Fig. 4.

a) and b) are surfaces before and after TM immobilization with top-coatings made by dip-coating in 2 wt% solution of CarboSil-Gly-COOH in DMAc/THF, respectively. The underlying layers of all coatings were doped with 8 wt% of DBHD/N2O2 and an equimolar amount of KTpClPB. c) Typical cross section of the SR catheter sleeves onto which the bilayer polymeric coatingwas applied. The thickness of the bilayer coating was approx. 35–50 μm. d) and e) are SEM micrographs of adhered platelets on polymeric coatings after 1 h incubation in sheep plasma. d) Control polymer with PurSil as the underlying layer and CarboSil-Gly as the top layer; e) Polymeric coating with its underlying layer made of PurSil doped with 8 wt % DBHD/N2O2 and its top layer made of CarboSil-Gly with surface-immobilized TM. The different roughness is due to different coating methods: a), b) and c) were dip-coated while d) and e) were spin-coated.