Abstract

Infra-red measurement systems are an established facet of operative procedures using surgical navigation, yet questions remain regarding their accuracy and everyday suitability. The importance of these systems has grown with the increasing popularity of minimally invasive procedures, which are associated with a reduction in operative field visibility. Even though these measurement systems are reliable and accurate, residual errors are still present and impact the overall success rate of surgical navigation. We performed empirical experiments to evaluate the effect of the error of digitization using a navigated probe on the accuracy of the predicted position and orientation of an acetabular cup. An accuracy of approximately 0.3 mm resulted in a potential error of 1.5 mm in predicted cup position and 0.2° in inclination. It is possible to estimate expected accuracy through the use of statistical methods and, as a result, to optimise procedures and test methods using this knowledge.

Introduction

Accurate alignment of the cutting, reaming, and inserting instruments is an important requirement for successful joint reconstruction surgery. This can be achieved using surgical navigation systems intraoperatively to assist the surgeon in determining correct implant position through precise three-dimensional measurement of various anatomical reference points (i.e., by kinematic analyses, probe measurements, or employing imaging methods such as the C-arm or ultrasound). Minimally invasive surgical techniques that reduce operative field visibility have increased the need for obtaining reliable and accurate measurements. The current study was designed to investigate the effect of probe accuracy in combination with a measurement system on implant alignment and placement during minimally invasive surgery.

Materials and methods

Procedure

We first used the so-called Monte Carlo method to predict the accuracy of spatial measurements performed with a navigated probe. Second, the influence of measurement errors on assessments of implant position and alignment was evaluated through theoretical and practical experiments. Finally, the effect of spraying with blood was simulated in a practical test.

Predicting the accuracy of a navigated probe

We used the Monte Carlo method of computer simulation to calculate the effect of errors in measuring the 3D position of individual tracker balls on the predicted location of a navigated probe. In general, this special method simulates the measurement procedure and takes into account the random effects of each source of error in this process. In this way, the method is able to predict the accuracy of the final measurements.

This method assumes a statistical distribution of data, in this case, points in space, and then calculates the resulting effect of errors in measuring the location of each point on the output of the navigation system. By examining the statistical distribution of these calculated data, it is possible to empirically determine how errors in the measurement of individual points affect the error of defining the position or orientation of bodies in space (e.g., the accuracy of implant placement). It is therefore also referred to as a statistical experiment method [5]. The method has the advantage of replacing practical and time-consuming measurements, and is especially useful for taking into account the numerous important and complex factors associated with surgical navigation.

The Monte Carlo method was used twice during this study: once to predict the accuracy of the measurement system in determining the position of the probe tip and again to predict the expected accuracy of a navigation system in measuring the inclination and anteversion of an acetabular cup.

The locations of the individual points (acquired using the inherent accuracy of the measurement system) were distributed in space to predict the resulting errors of the system. The distribution of predicted locations of the tip of a navigated probe was calculated with variations in both the length of the probe tip (d[mm] in Fig. 1) and the accuracy of the tracker system in measuring the position of each marker ball attached to the probe.

Fig. 1.

Scatter of the probe tip at various accuracy levels of the measurement systems

Two commercial measuring systems of different levels of accuracy were modelled using the Monte Carlo procedure. The first model system (Polaris, NDI) has an inherent measurement accuracy of 0.35 mm (RMS), whereas the second system has an accuracy of 0.12 mm [CamBar (Axios 3D) Optotrac Certus (NDI) [3, 6]]. The computer simulation predicted that for systems with an accuracy of 0.35 mm, the accuracy in tip location would be ~0.7 mm (1 sigma) when using a probe tip of 190 mm in length. With a measurement accuracy of 0.12 mm, the error in tip location would be reduced to ~0.3 mm (1 sigma). Assuming a Gaussian distribution of the data, it can be statistically assumed that ~67% of all probe values are within this theoretical accuracy, with 99.8% of the data falling within ~0.9 mm (3 sigma). This means that, when 1,000 patients are operated with an accuracy specification of 1 sigma, the results of 670 patients are correct, while with 3 sigma the results of 980 patients are within the given accuracy.

Practical testing

The accuracy of the different navigation systems was evaluated using a simple practical test that entailed measuring the location of a hole in a metal plate using a handheld navigation probe (length: 190 mm) [7]. The plate was fixed relative to the navigation system and measurements were taken using both the Polaris (NDI) [6] and CamBar (Axios 3D) systems [3]. Numerous measurements were taken by touching the handheld probe around the edges of the hole. The measurements were then recorded and averaged.

Effect of marker contamination

The accuracy of all measurements performed with infra-red navigation systems depends on the quality of the images received from the retro-reflective spheres mounted on navigated instruments [1]. Intraoperative contamination of these markers with droplets of blood causes an immediate loss of reflective properties, with profound effects on the accuracy of the surgical navigation system. To evaluate the accuracy of the measurement system under realistic intraoperative conditions, the measurement trials were repeated after controlled degrees of contamination of the marker balls mounted on the probe. Blood was simulated with water drops from a commercially available spray bottle.

System intelligence

To minimise the influence of sources of errors, such as contaminated spheres, computer routines can be performed to continuously monitor the quality of the marker data, with elimination of erroneous data points. One such strategy has been incorporated in the CamBar system [3]. In this case, the expected reflection of the reflective spheres is compared to the actual reflection. In addition, the system checks the contour geometry of the marker balls. An undamaged sphere is seen by the system as an ellipsoidal image, while a damaged or contaminated ball does not maintain this geometry. Furthermore, the exactness of the position of the intersection of the stereo measurement system’s image rays (the intersection accuracy) is evaluated [2, 4]. Taking this information into account, the markers are classified by the system (Fig. 2). Deviations greater than 0.6 mm are recognised by the system and can thus be excluded from any calculations.

Fig. 2.

Scatter of the probe tip when spraying with blood is simulated. Class 1 represents a brand new marker while class 6 is assigned to poorly performing markers

Relevance for cup placement

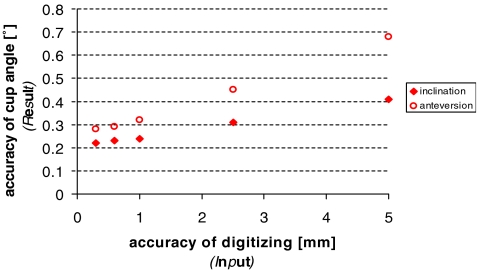

Using the Monte Carlo method, the accuracy of navigated measurements of cup position and alignment were calculated for different levels of error of the measurement probe, ranging from 0.3 mm to 5 mm. The 3D positions of the iliac crests, the pubic symphysis, and the acetabular margin were dispersed statistically to 0.3, 0.6, 1.0, 3.0, and 5.0 mm with 1,000 repetitions each.

Results

Practical testing

Results of the practical testing of the accuracy of the different navigation systems are provided in Fig. 3. The differences of 0.6 mm are well within the value of 0.7 mm quoted for the Polaris system. The same applies for the Cambar system, where the differences at 0.25 mm are also well below the predicted standard deviation of 0.3 mm. These resulting deviations were clearly lower than those predicted by the Monte Carlo method. The measurement results represent the deviation from the mean point, instead of the deviation from the setpoint value. For this reason, the empirical data showed better accuracy when compared with the data predicted by the Monte Carlo method.

Fig. 3.

Practical testing of simulation with a probe tip length d=190 mm

Effect of marker contamination

Only a slight (0.1 mm) deviation was obtained at the lowest levels of marker contamination, but the error of the navigated measurements increased by up to 5 mm as the severity of contamination increased. Therefore, deviations of up to 15 mm can be assumed for a 3-sigma limit (covering 99.8% of all measurements). These deviations can cause an inaccurate implant position during navigation, confirming the need for suitable methods for real-time error detection and correction.

Relevance for cup placement

The predicted results of hip navigation in measuring the position and alignment of the acetabular cup are shown in Figs. 4 and 5, respectively. Figure 5 shows that even a 5-mm range of dispersion of the probe permits a standard deviation of less than 1° for inclination and anteversion and that an accuracy of 0.3 mm is associated with a 0.2° error in inclination. Additionally, probing inaccuracies had little effect on implant alignment; however it is clear from Fig. 4 that standard deviations in cup placement of 1.5 mm to 2.5 mm are possible when the measurement accuracy of the probe itself is only 0.3 mm to 1 mm. Presumably, these inaccuracies will not be clinically relevant if no additional errors (e.g., contamination of spheres) lead to poor implant position and alignment.

Fig. 4.

Accuracy of implant placement depending on probing accuracy

Fig. 5.

Accuracy of implant alignment depending on probing accuracy

Conclusion

These investigations show that the net accuracies of contemporary infra-red navigation systems are adequate for implant positioning. However, an intelligent system is required to assure accurate implant placement in the face of intraoperative contamination of the retro-reflective marker arrays.

Conversely, users of non-intelligent systems must pay extreme attention to the quality of the measurement markers. Because surgeons experience less operative field visibility during minimally invasive operation techniques, the use of intelligent measuring systems may gain in importance in assuring the accuracy of measurements performed with navigation systems.

Acknowledgements

We would like to thank Prof. Thomas Luhmann, Ute Greve-Luhmann, and Dr. N. Heinz for their proof-reading and helpful comments. Also we would like to thank all members of the Axios Project group, whose good work enabled this article.

Footnotes

An erratum to this article can be found at http://dx.doi.org/10.1007/s00264-007-0464-0

References

- 1.3M Deutschland GmbH (2005) Was ist Retroreflexion? Technologien. In: 3M Deutschland GmbH (eds) Funktionsweise Retroreflexion. 3M Deutschland GmbH, Carl- Schurz- Strasse 1, 41453 Neuss URL: http://solutions.3m.com/wps/portal/!ut/p/kcxml/04_Sj9SPykssy0xPLMnMz0vM0Q9KSY13cdWP0I8yizeINzWw1C_IcFQEAEmGTCU!; last accessed: 06.12.2006

- 2.Albertz J, Kreiling W (1989) Physik; Photogrammetric techniques. In: Albertz J, Kreiling W (eds) Photogrammetric guide, 4th edn. Wichmann Verlag, Karlsruhe, pp 60–86 and pp 162–235

- 3.AXIOS 3D Services GmbH (2006) CamBar- optical measurement system. In: AXIOS 3D Services GmbH (eds) Product information. AXIOS 3D Services GmbH, Marienstr. 16, D-26121 Oldenburg; URL: http://www.axios3d.de/downloads/flyer/CamBarEn.pdf

- 4.Luhmann T, Robson S, Kyle S, Harley I (2006) Stereoscopic processing. In: Luhmann T, Robson S, Kyle S, Harley I (eds) Close range photogrammetry- principles, techniques and applications. Whittles Publishing, Dunbeath, pp 274–283

- 5.Lutz M (2000) Monte-Carlo-Methode. In: Lutz M, Börgens M, Malerczyk C, Emmel S (eds) Interaktive Mathematik- Beitrag zum "World Mathematical Year 2000". FB MND, FH Giessen-Friedberg, URL: http://www.fh-friedberg.de/users/mlutz/wmy2000/index_IntMathe.htm; last accessed: 06.12.2006

- 6.Northern Digital Inc (2006) Passive polaris. In: Northern Digital Inc (eds) Product information- comparison of polaris system specifications. Northern Digital Inc., International Headquarters, Randall Drive 103, Canada N2V 1C5

- 7.Plus Orthopedics (2005) PIGalileo. In: Plus Orthopedics (eds) Product information-PiGalileo Computergestützte Orthopädische Chirurgie. Precision Implants AG, Schachenallee 29, CH-5000 Aarau, Switzerland