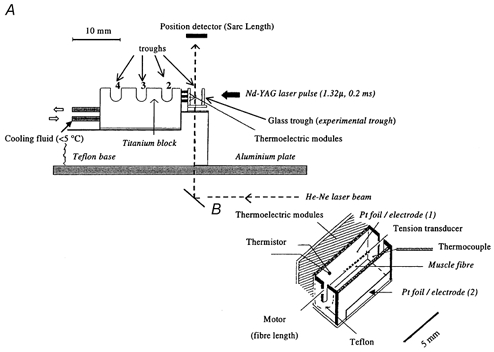

Figure 1. A schematic diagram of the trough system used in laser T-jump experiments.

A, the system consists of three troughs milled in a titanium block and a front trough that was built with glass front and bottom windows and used as the experimental trough. Cooling fluid, circulated within the titanium block, acted as a heat sink. The trough system was fixed on a Teflon block (a heat insulator), that could be moved along the aluminium plate by a lever mechanism (not shown) to expose, in skinned fibre experiments, a preparation to different solutions. B, an enlarged view of the front glass experimental trough. An intact fibre bundle was attached, by aluminium foil clips, between two metal hooks, one connected to a force transducer and the other to a servomotor. The experimental trough temperature was clamped using thermoelectric modules that were under thermistor feedback control, and it was monitored by a thermocouple placed near the fibre bundle. Supramaximal voltage stimuli (0.2–0.5 ms) were delivered via two platinum foil electrodes glued to the front window and the back wall of the trough, the one in the front window being narrower to prevent fibre shadowing by the heating laser pulse. The Nd-YAG laser pulse (λ= 1.32 μ, pulse duration = 0.2 ms, elliptical cross-section ∼2 mm × 5 mm) entered through the front window, it was partially absorbed in solution and reflected by the platinum foil on the back wall. The transducer hooks and the aluminium T-clips were shadowed from the laser beam (not shown). The energy absorption of ∼50 % during the 0.2 ms pulse heated the solution and fibre bundle by 3–5 °C and the elevated temperature in the trough solution remained constant for ∼500 ms (for details see Ranatunga, 1996).