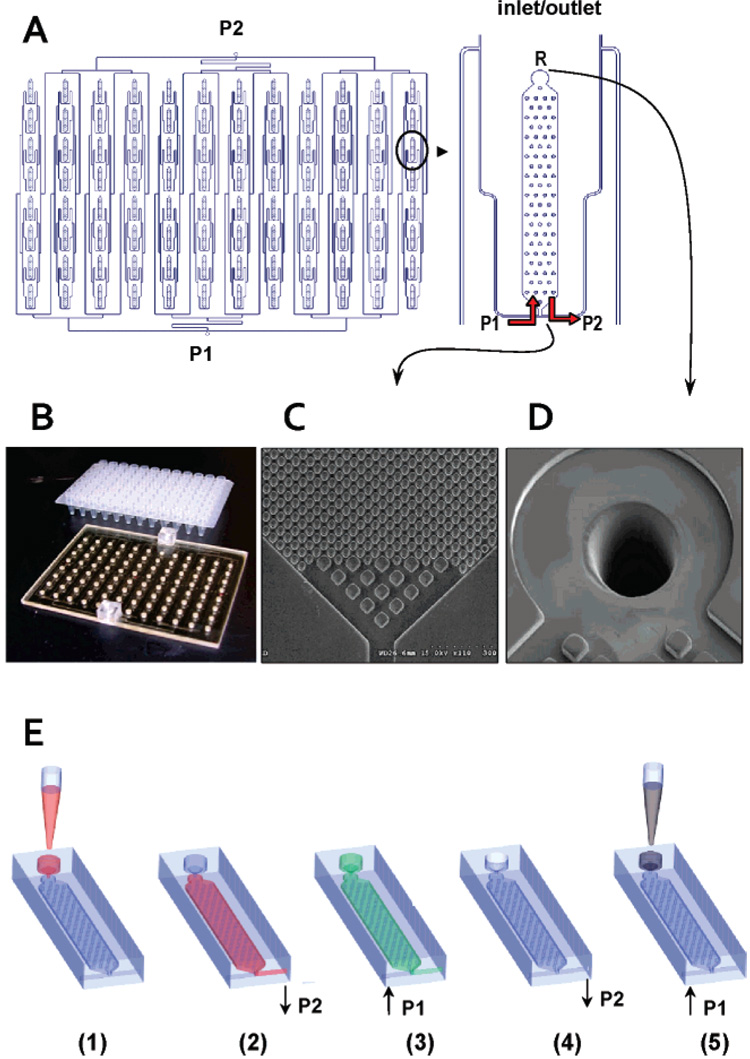

Figure 1. Layout of the 96-well PPC-SPRI titer plate-based microfluidic platform.

(A) Schematics of the individual immobilization beds and microfluidic control ports, P1 and P2. R is the sample inlet/outlet reservoirs. (B) Brightfield image of the 96-well PPC-SPRI microfluidic plate and a commercial 96-well titer plate. (C–D) SEMs of the entrance/exit section of the plate showing 20 µm posts and 50 µm entrance posts along with a ~150 µm bed entrance hole drilled using a KrF excimer laser. (E) Schematic showing the operation of the 96-well plate: (1) sample is introduced into the reservoir (R); (2) sample is pulled toward port P2 using a vacuum pump, and DNA/RNA is immobilized onto the extraction bed surface; (3) ethanol is pushed from port P1 to R using a syringe pump to wash the extraction bed; (4) ethanol in the extraction beds and in R is evacuated by using a vacuum pump through P2, and then the beds are dried by pulling air through P2; (5) effluent (water) is pushed from port P1 to R and purified NAs are collected.