Table 3.

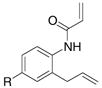

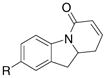

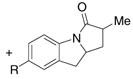

Carboamination of o-allyl vinyl amidesa

| entry | substrate | product(s) | yieldb(selectivity) | |

|---|---|---|---|---|

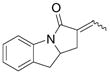

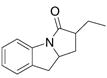

|

|

|

||

| 1 | 9a, R = H | 10a, R = H | 11a, R = H | 72%(10a:11a = >20:1) |

| 2 | 9b, R = OMe | 10b, R = OMe | 11b, R = OMe | 74%(10b:11b = >20:1) |

| 3 | 9c, R = Cl | 10c, R = Cl | 11c, R = Cl | 71%(10c:11c = >20:1) |

| 4c | 9a, R = H | 10a, R = H | 11a, R = H | 56%(10a:11a = 1.2:1) |

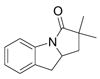

| 5c |

12 |

13 |

38% | |

| 6c |

14 |

15 |

16 |

49%(15:16 = 2.5:1) |

Conditions. Substrate in DMF (0.1 M) was treated with Cu(EH)2 (3 equiv) and Cs2CO3 (1 equiv). The mixture was heated to 140 °C for 24 h in a pressure tube.

Yields refer to the sum of products isolated by chromatography on SiO2. The remainder of the material was either starting olefin or olefin-isomerized starting material.

Heated to 190 °C for 24 h.