Table 4.

Carboamination of aliphatic imides and amides.a

| entry | substrate | product(s) | yieldb(selectivity) | |

|---|---|---|---|---|

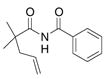

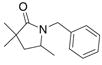

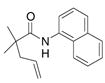

| 1 |

17 |

18 |

81% | |

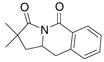

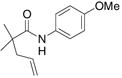

| 2c,d |

19 |

20 |

21 |

70%(20:21 = 1.6:2) |

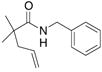

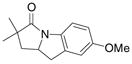

| 3c,e |

22 |

23 |

24 |

83%(23:24 = 3.3:1) |

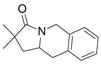

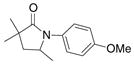

| 4c,e |

25 |

26 |

27 |

79%(26:27 = 3.4:1) |

| 5c |

28 |

29 |

56% | |

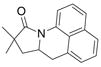

| 6 |

30 |

31 |

81% | |

| 7c |

32 |

33 |

74% | |

Conditions. Substrate in DMF (0.1 M) was treated with Cu(EH)2 (3 equiv) and Cs2CO3 (1 equiv). The mixture was heated to 120 °C for 24 h in a pressure tube.

Yields refer to the sum of products isolated by chromatography on SiO2. The remainder of the material was either starting olefin or olefin-isomerized starting material.

Heated to 190 °C.

Reaction run for 72 h.

tbutyl benzene was used as solvent.