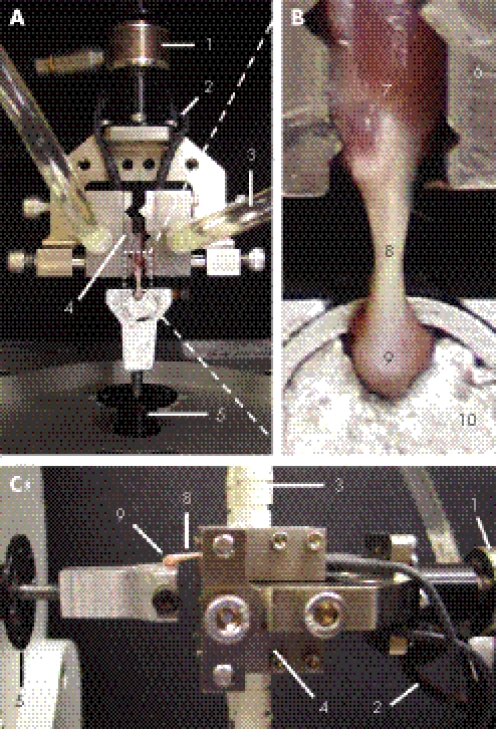

Figure 4 Example experimental set‐up for mechanical testing of a rat Achilles tendon: (A) view from above; (B) magnified view of the muscle‐tendon‐bone complex from above; (C) side view. A muscle‐tendon‐bone complex was harvested by transecting the calcaneus and mid‐belly of the gastrocnemius‐soleus muscles. The complex was fixed to a materials testing device. The calcaneus was embedded in a fixture containing a low‐melting point alloy, while the gastrocnemius‐soleus muscles were clamped in a thermal‐electrically cooled tissue grip. The latter grip uses a thermal‐electric cooling device to cool and freeze the specimen tissue within the jaw area. The frozen tissue takes on the serpentine shape of the jaw faces, thereby preventing slippage during tensile testing of the tendon. 1 = load cell (225 N); 2 = electrical wires for thermal‐electrical cooling of the grip surfaces; 3 = circulating water that facilitates heat removal from the grips; 4 = titanium tissue grips; 5 = computer controlled actuator; 6 = serpentine grip surfaces; 7 = gastrocnemius‐soleus muscle complex; 8 = Achilles tendon; 9 = calcaneus fixed at 90° to Achilles tendon; 10 = Wood's low‐melting point alloy used to fixed the calcaneus.

An official website of the United States government

Here's how you know

Official websites use .gov

A

.gov website belongs to an official

government organization in the United States.

Secure .gov websites use HTTPS

A lock (

) or https:// means you've safely

connected to the .gov website. Share sensitive

information only on official, secure websites.