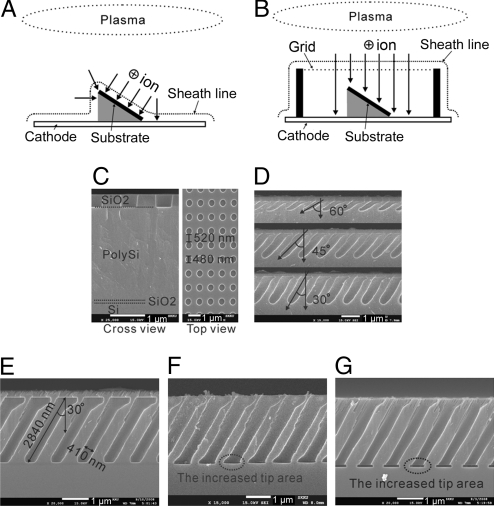

Fig. 1.

Mechanism and fabrication results of angled etching technique. (A) An illustration of the plasma sheath without a Faraday cage. Ions are incident on the substrate surface in a direction normal to the substrate surface. (B) An illustration of the plasma sheath with a Faraday cage. Ions are incident on the substrate surface in a direction normal to the grid plane. (C) SEM images of polySi substrates used in the etching experiment. (D) SEM images of polySi etch profiles with angles of 30°, 45°, and 60°. The images indicate that the angle of etch profiles can be controlled by using the Faraday cage system. (E–G) SEM images of polySi masters for the fabrication of nanohairy structures. Etch profiles have an angle of 30° and an aspect ratio of 6.9 (etch depth = 2,840 nm; the hold CD = 410 nm), as shown in E. By using the etch-stop layer, the flat bottom surface was obtained. The surface area of the bottom could be further increased by an over-etching of the polySi (F) and a wet etching of the etch-stop layer (G).