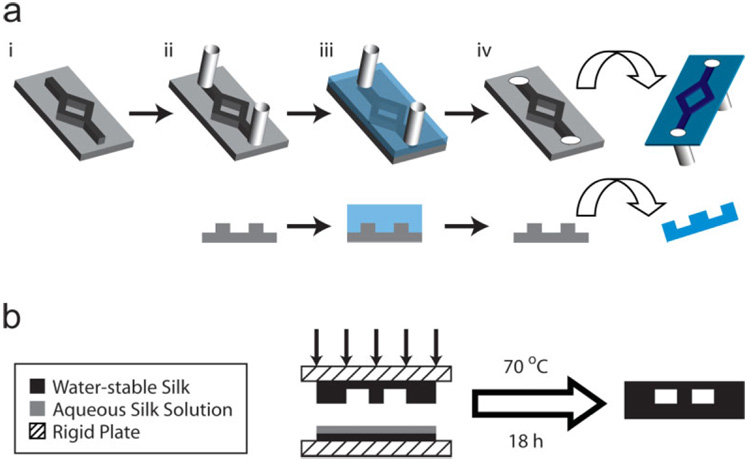

Figure 1. Fabrication Strategy for Silk Fibroin Microfluidic Devices.

a) The process flow is diagrammed in both an isometric view and a cross-sectional view through the midline (i) through the successive steps of the process. PDMS negative molds (i) are fabricated using traditional soft lithography techniques (not shown). PDMS molds are modified with silicone tubing (ii) prior to solvent casting of aqueous silk fibroin solution (iii). Upon water evaporation, micromolded films are delaminated with integrated macroscopic fluidic connections (iv). Both micromolded and flat silk films are treated with aqueous methanol solutions (see text). b) Final assembly of silk microfluidic devices was performed by bonding appropriate water-stable silk fibroin layers using additional regenerated aqueous silk fibroin solution. Layers are bound between rigid plates under mechanical pressure at 70 °C for 18 h to produce a water-insoluble silk fibroin interface with increased β-sheet content (see text).