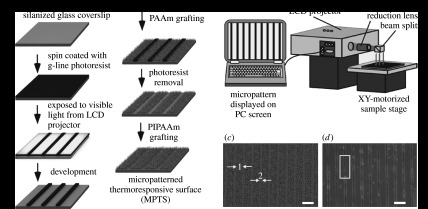

Figure 9.

Microfabrication process used to create thermoresponsive micropatterned surfaces. (a) Schematic of the microfabrication process used to create micropatterned surfaces. Photoresist patterns on silanized coverslips are created using a rapid prototyping micropattern exposure system comprising a modified LCD projector and XY-motorized sample stage described in (b). Polyacrylamide (PAAm) is selectively covalently grafted onto the non-photoresist-coated regions of the silanized coverslip. After lift-off and cleaning of the photoresist, PIPAAm is covalently grafted onto the silanized coverslip. (c) Microscopy of visualized pattern formation onto micropatterned surfaces caused by water condensation onto the zones of different surface hydrophilicity: PAAm-grafted 60 μm-wide lane in (1) and PIPAAm-grafted 20 μm-wide lane in (2). (d) Cultured ECs on 20 μm-wide adhesive thermoresponsive domains at 37°C. Adapted from Tsuda et al. (2007).