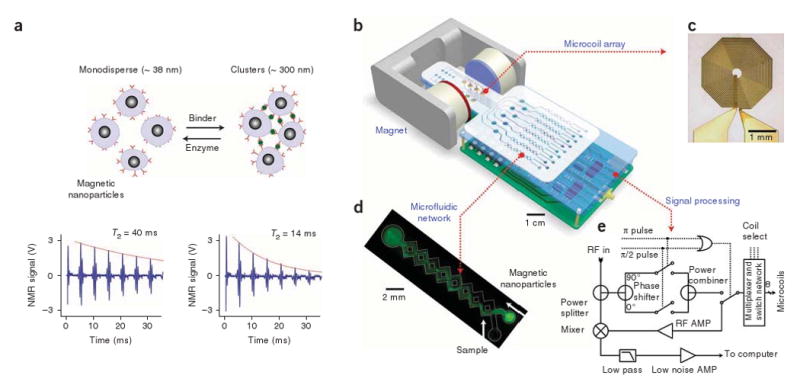

Figure 1.

Principle of the assay and structure of the DMR system. (a) Principle of proximity assay using magnetic particles. When monodisperse magnetic nanoparticles cluster upon binding to targets, the self-assembled clusters become more efficient at dephasing nuclear spins of many surrounding water protons, leading to a decrease in spin-spin relaxation time (T2). The bottom panel shows an example of the proximity assay measured by the DMR system. Avidin was added to a solution of biotinylated magnetic nanoparticles, causing T2 to decrease from 40 ms to 14 ms. (b) Schematic diagram of the DMR system. The system consists of an array of microcoils for NMR measurements, microfluidic networks for sample handling and mixing, miniaturized NMR electronics and a permanent magnet to generate a polarizing magnetic field. The entire setup can be packaged as a handheld device for portable operation (for clarity, the structure of the magnet is simplified). (c) High resolution image of an actual microcoil. The microcoil generates radio frequency (RF) magnetic fields to excite samples and receives the resulting NMR signal. To reduce electrical resistance and hence thermal noise, the metal lines were electroplated with copper. (d) Example of a microfluidic network. Effective mixing between magnetic particles and the target analytes is achieved by generating chaotic advection through the meandering channels. The channel also helps confine the mixture in the most sensitive region of the microcoils, increasing filling factors. (e) Schematic of the NMR electronics. The circuit is designed to perform T2 and T1 measurements via CPMG and inversion-recovery pulse sequences, respectively. AMP, amplifier.