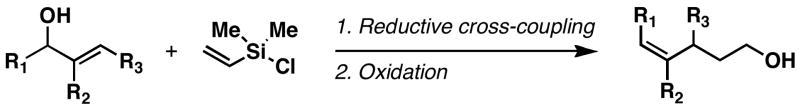

Table 2.

| |||||

|---|---|---|---|---|---|

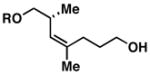

| entry | allylic alcohol | vinylsilane | yield (%)a | (Z:E) | product |

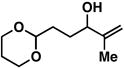

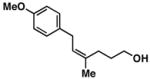

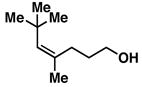

| 1 |

14 |

20 | 51 | ≥ 20:1 |

26 |

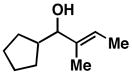

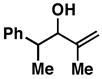

| 2 |

16 |

20 | 58 | ≥ 20:1 |

27 |

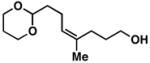

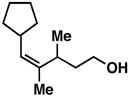

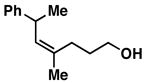

| 3 |

28 |

20 | 69 | ≥ 20:1 |

29 |

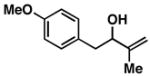

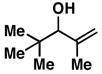

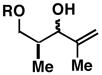

| 4 |

30 |

20 | 56 | ≥ 20:1 |

31 |

| 5 |

3211 |

20 | 64 | ≥ 20:1 |

33 |

|

|

||||

| 6 | 34; R = TBS11 | 20 | 66 | ≥ 20:1 | 37; R = H |

| 7 | 35; R = TBDPS11 | 20 | 61 | ≥ 20:1 | 37; R = H |

| 8 | 36; R = PMB11 | 20 | 61 | 1.2:112 | 38; R = PMB |

Yield reported is over the two-step process: 1) Reductive cross-coupling (20, ClTi(Oi-Pr)3, c-C5H9MgCl, Et2O (−78 to −50 °C), then cool to −78 °C and add lithium alkoxide of the allylic alcohol (−78 to 0 °C) then, HCl (1N)), 2) oxidation (t-BuOOH, CsOH·H2O, TBAF, DMF, 70 °C).