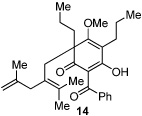

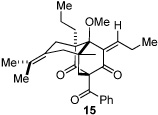

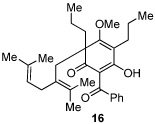

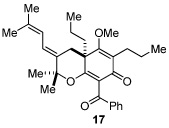

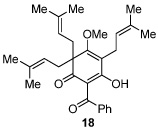

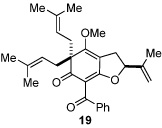

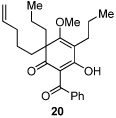

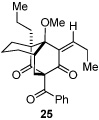

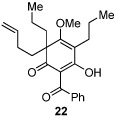

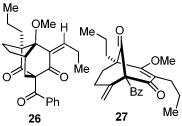

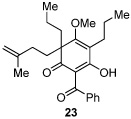

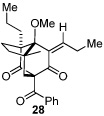

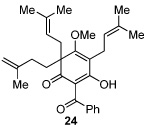

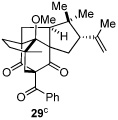

Table 2.

Scope of the Mn(III)-mediated cycloaddition

Reaction conditions: Mn(OAc)3·2H2O (2.1 equiv), Cu(OAc)2·H2O (1.0 equiv), AcOH, rt, 4 h.

Reaction performed at 65 °C for 15 min.

Reaction performed at 35 °C for 4 h.

dr = 4:1 (major diastereomer shown).