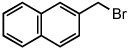

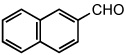

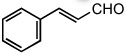

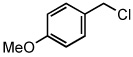

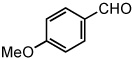

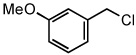

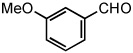

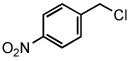

Table 1.

Reduction of Benzylic and Allylic Halides with Pyridine N-Oxide in CH3CN

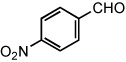

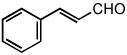

| Entry | Substrate | Product | Temperature | Yield (isolated) |

|---|---|---|---|---|

|

|

|||

| 1 | R = H | 25 °C | 82% | |

| 2 | R = p-Br | 25 °C | 80% | |

| 3 | R = p-CO2CH3 | 25 °C | 81% | |

| 4 | R = m-CN | 50 °C | 84% | |

| 5 | R = p-CN | 50 °C | 80% | |

| 6 | R = m-NO2 | 50 °C | 86% | |

| 7 | R = p-NO2 | 50 °C | 86% | |

| 8 |  |

|

25 °C | |

| 9 |  |

|

25 °C | 84% |

| 10 |  |

25 °C | 85% | |

| 11 |  |

|

25 °C | 85% |

| 12 |  |

|

50 °C | 92% |

| 13 |  |

|

50 °C | 74%a |

| 14 |  |

|

50 °C | 75%b |

| 15 |  |

50 °C | 95% | |

The yield is based on 71% converted starting material.

The yield is based on 50% converted starting material.