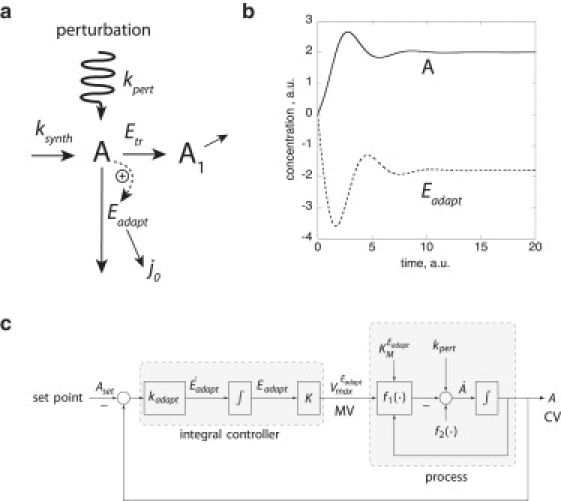

Figure 2.

(a) Reaction scheme of system with rate Eqs. 1 and 2. Species A is formed by a zero-order process with rate constant ksynth and then transformed to the product A1. Rate constant kpert is related to a perturbing process (wavy line), which increases the level of A. To remove excess A, A is forming enzyme species Eadapt, which removes A with the flux (indicated by the vertical arrow). To get robust adaptation in A independent of kpert, Eadapt is removed through a zero-order flux j0 = kadaptAset. (b) Calculation showing that negative Eadapt concentrations may arise when Aset is regarded as a fixed setpoint. Initial concentrations of A and Eadapt are zero; kadapt = 5, kpert = ksynth = 0.5, , = 1, = 110, = 100, and Aset = 2. Concentration and timescales are in arbitrary units (a.u.). (c) Scheme of the adaptive process shown in panel a containing the setpoint Aset, the integral controller and the process units. The controlled variable (CV) is A. Eqs. 1 and 2 are written as dA/dt = f2(·) – f1(·) + kpert, dEadapt/dt = kadapt(A – Aset), respectively, with , , and = K · Eadapt. K is the turnover number for Eadapt, i.e., . MV: manipulated variable.