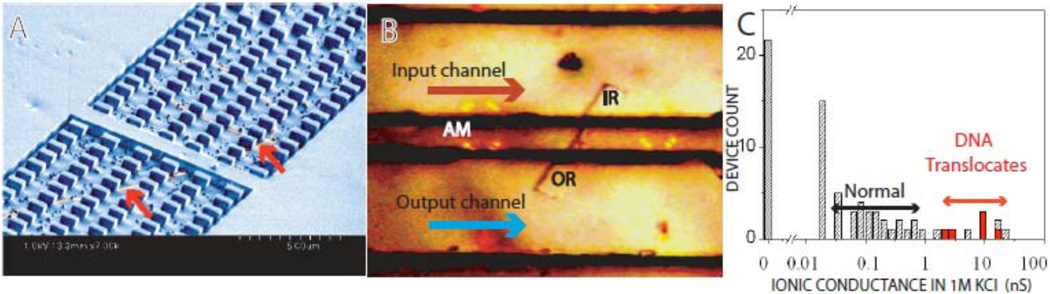

Fig. 1.

A. A single nanopore device was fabricated by growing SWCNTs at low densities on an oxidized Si wafer. We used cobalt catalyst particles with ethanol vapor as the carbon source in conditions most likely to produce high-quality SWCNTs with an outside diameter of 1 to 2 nm (30). A 700 nm layer of PMMA resist is spun on and reservoirs opened over selected tubes with electron beam lithography. The exposed regions of SWCNTs were removed by O2 plasma etch. The SEM image of the device shows a 2 µm barrier prior to removal of the exposed SWCNT (pointed to by arrows). Pillars in the reservoir support the PDMS cover. B. Optical micrograph taken through a PDMS cover. The reservoirs (“IR” = input, “OR” = output) span the barrier between PDMS channels at an angle of about 60°. “AM” marks the location of one set of alignment markers. C. Current flows through the single SWCNTs and not a leakage path. With the SWCNT bridging the gap and opened, most tubes pass currents in the expected range (“Normal”), but 20% pass unexpectedly large currents. Some of these (marked in red) also passed DNA oligomers. These data are limited to the subset of devices exposed to short plasma etches for which control experiments show no leakage (supplementary information).