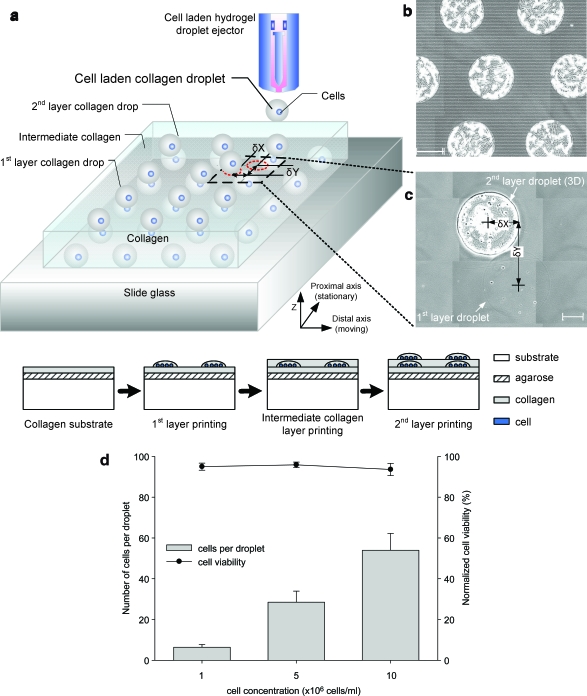

FIG. 2.

Printing platform for 3D cell-laden droplet printing. (a) Cell-laden hydrogel droplets are generated by a mechanical valve that is operated by a controlled pulse width (open period of the valve) and a frequency (on/off time of the valve) to generate required volume and timed placement of droplets onto a substrate, respectively (Fig. 1). Droplets are printed to form multiple layers of collagen; smooth muscle cell (SMC)–laden collagen droplet array (gray color sphere), intermediate collagen layer, and top SMC-laden droplet layer (blue color sphere). Image of a printed array of collagen droplets (b) and image of a multilayered array on a slide glass (c). A gray-colored droplet indicates the bottom layer of collagen shown in (c). δx and δy are measured between centers of each droplet in different layers. Mean and standard deviation values of x (distal axis) and y (proximal axis; moving axis) directional variations were 0.5 ± 4.9 and 18.0 ± 7.0 μm, respectively. (d) Number of cells per droplet and cell viability as a function of loading concentrations. Mean and standard deviation values of encapsulated cells were 6 ± 1, 29 ± 5, and 54 ± 8 cells per droplet in 1 × 106, 5 × 106, and 10 × 106 cells/mL, respectively. The cell printing platform showed 94.8 ± 0.8% average cell viability for three different concentrations compared to the culture flask. Each cell loading concentration had 94.9 ± 1.7%, 95.8 ± 1.3%, and 93.5 ± 3.0% cell viability. Scale bar: 200 μm. Color images available online at www.liebertonline.com/ten.