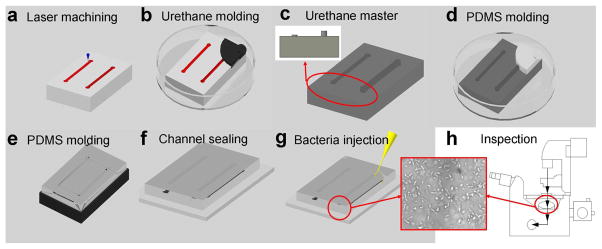

Figure 2.

Process flow for fabricating microfluidic channels with different S/V ratios for rapid AST. (a) A CO2 laser machining system was used to engrave microchannels on a polycarbonate substrate. Different channel depths can be generated simultaneously in the process. (b) Urethane molding on the polycarbonate master. (c) A reverse, urethane mold with microchannels of different depths. Only two channels are shown for simplicity. The insert shows the cross-section view. (d–e) PDMS channels were molded on the urethane mold. (f) The PDMS channel was sealed with a glass substrate using an atmospheric (air) plasma system. The plasma treatment step also sterilized the channel. (g) Injection of pathogens into the channel with a syringe. Microchannels were washed with PBS and incubated with or without BSA before the experiment. (H) Bacterial growths can be monitored by phase contrast microscopy or absorbance spectroscopy.