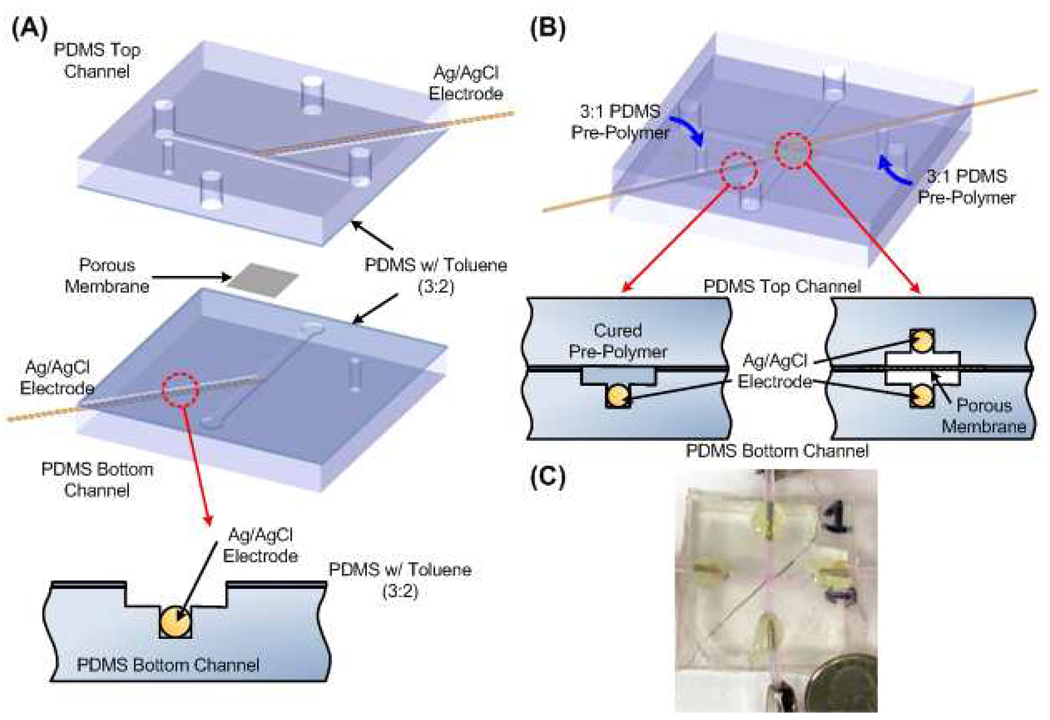

Figure 2. Fabrication Overview.

(a) Device Bonding. Ag/AgCl wire electrodes were set into grooves of the same diameter fabricated within side channels. Upper and lower slabs were bonded using PDMS: Toluene stamping procedure. Chip was cured overnight at 60°C tightly bonding upper and lower slabs. (b) Securing Embedded Electrodes. 3 (PDMS prepolymer) : 1 (PDMS curing agent) was injected into the side channels. Flow was discontinued before PDMS prepolymer immersed the tip of the electrode or entered the main channel. Chip was elevated slightly during curing to prevent liquid polymer from draining into the main channel. Steps were repeated for the opposite electrode (orientation of the elevation was also switched). (c) Photograph of fabricated device.