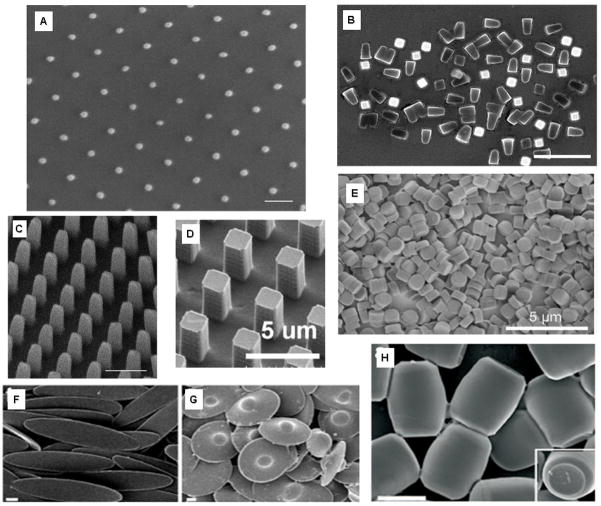

Figure 2. Various shape and size specific nanoparticles fabricated using S-FIL, PRINT and Solvent Molding.

(A–C) Modified Step and Flash Imprint Lithography (S-FIL) fabricated nanoparticles composed of 75%(v) PEG-diacrylate.[54]: (A) 50 nm × 50 nm × 100 nm pillars, (scale bar = 100 nm), (B) 400 nm × 400 nm × 525 nm particles released from the substrate (scale bar = 2μm), (C) 200 nm × 200nm × 525 nm pillars (scale bar = 500 nm); (D–E) Particle replication in non-wetting templates (PRINT) process: (D) 2 μm wide pillar PRINT particles that are composed of insulin (25%wt) (scale bar = 5 μm) [65], (E) 1 μm diameter by ~500 nm long cylindrical particles composed of 67 wt% trimethylolpropane ethoxylate triacrylate, 20 wt% PEG monomethylether monometharcylate, 10 wt% aminoethyl methacrylate hydrochloride, 2 wt% fluorescein-o-acrylate, and 1 wt% 2,2-diethoxyacetophenone (scale bar = 5 μm) [124]; (F–H) Non-spherical particle geometries formed by solvent molding-based manipulation of spherical polystyrene particles: (F) Elliptical disks (scale bar = 2 μm) [61], (G) “UFOs” (scale bar = 2 μm) [61], and (H) Barrels (scale bar = 2 μm) [61].