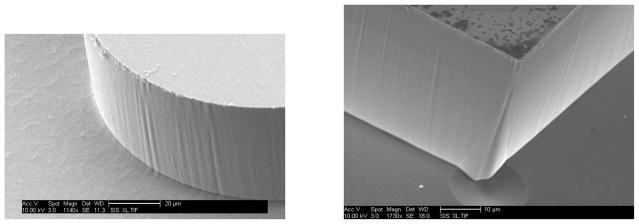

Fig. 2.

Edge of a cryogenically-etched mold for a lens (left) and a waveguide (right). Larger scale ripple is the result of lithography problems, not limitations of the cryogenic process. The waveguide (right) still has the metal mask coating on the top along with some fragments around it, which are all removed by a wet etching process after the initial etch. Note the highly vertical sidewalls in of the lens, and the excellent smoothness of the waveguide