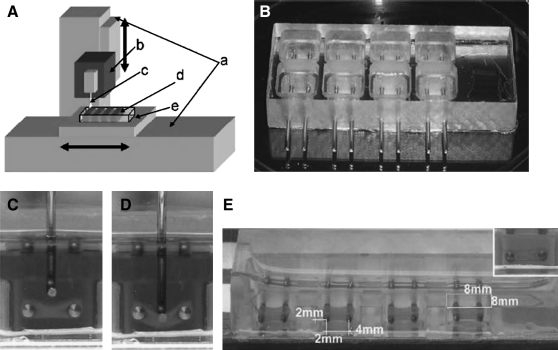

FIG. 2.

Hydrogel tissue construct (HTC) mechanics. (A) Schematic of the force measurement device. a, Linear actuator moved by a servo motor (±70 μm accuracy); b, isometric force transducer; c, force probe; d, tissue chamber; e, warming plate (37°C) connected to a water circulation bath. The device can automatically indent four samples in one row, and the operator manually translates the mold to the next row. A computer records the force response measured by the isometric transducer and regulates the speed of indentation. (B) Tissue chamber for producing and testing engineered tissues. (C) A force probe approaching an HTC formed between two stainless steel bars. (D) The probe indents the HTC vertically and stretches it longitudinally. (E) The typical size of HTCs was approximately 4 × 4 × 0.8 mm (length × width × thickness), and they are formed in 8 × 8 mm (opening) square wells in the tissue chamber. Reprinted with permission from Ref.36