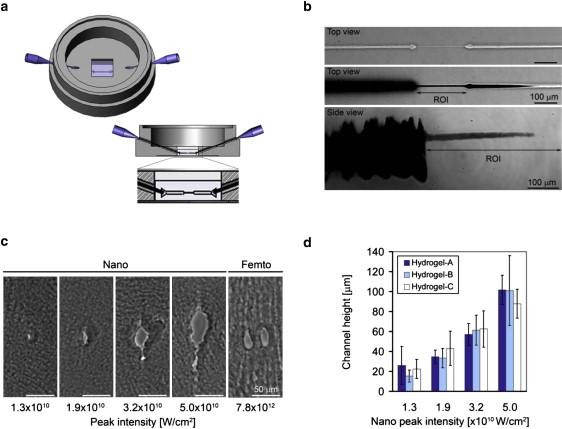

Figure 2.

Characterizing microchannel dimensions and morphology. (a) A schematic illustration of the microfluidics apparatus used to characterize microchannel dimensions is shown; the cross-section illustration shows the square hydrogel sample relative to the location of the ablated microchannel in the center and middle of the gel. (b) The top view of a hydrogel-A sample (nanosecond laser ablation at 1.9 × 1010 W/cm2) with a characterized channel before (upper panel) and after (middle panel) injection of black ink; the side view (lower panel) of a characterized microchannel after injection of ink is also shown (scale bar = 100 μm) with the highlighted region of interest (ROI) where the microchannel is created in between the larger inlet and outlet channels. (c) Histological cross sections of microchannels made within a hydrogel-B sample using different nanosecond (left) or femtosecond (right) laser energy levels (W/cm2) are shown. The morphology of the microchannel is nonuniform and the height/width ratio is >1; two side-by-side microchannels made with the femtosecond system are shown (scale bar = 50 μm). (d) A quantitative characterization of the microchannel cross sections shows a statistically significant increase in microchannel height with increasing nanosecond laser energy levels in all hydrogel compositions tested (p < 0.01, n ≥ 3). A comparison of the channels made in the different hydrogel compositions using the same nanosecond laser energy level reveals no significant difference in microchannel height (p > 0.3, n ≥ 3).