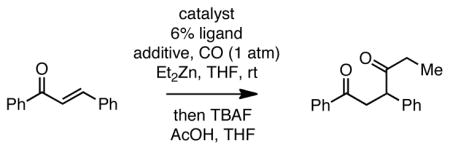

Table 1.

Effect of Reaction Conditions on Carbonylative Conjugate Additions to Chalconea

| ||||

|---|---|---|---|---|

| entry | catalyst | ligand | additive | % yield |

| 1 | 5% Pd(PPh3)4 | - | TMSCl+LiCl | 70 |

| 2 | 5% Pd(PPh3)4 | - | TMSCl | 82 |

| 3 | 5% Pd(PPh3)4 | - | - | N.R. |

| 4 | 2.5% Pd2(dba)3 | PPh3 | TMSCl | 85 |

| 5 | 2.5% Pd2(dba)3 | PCy3 | TMSCl | 82 |

| 6 | 0.25% Pd2(dba)3 | PPh3 | TMSCl | 86 |

| 7 | 0.25% Pd2(dba)3 | PCy3 | TMSCl | 86 |

| 8 | 2.5% Pd2(dba)3 | PCy3 | TMSCl | 83b |

| 9 | 5% Ni(cod)2 | PCy3 | TMSCl | N.R. |

| 10 | 5% Pt(dba)3 | PCy3 | TMSCl | 0 |

Reaction with 1.3 equiv Et2Zn, 2.3 equiv TMSCl, 1 atm CO, for 4 h. Subsequent to reaction, the mixture was quenched at 0 °C with acetic acid (1.5 equiv) and TBAF (1.5 equiv) for 10 minutes and then treated with saturated Na2CO3.

Reaction with 0.65 equivalents of Et2Zn.