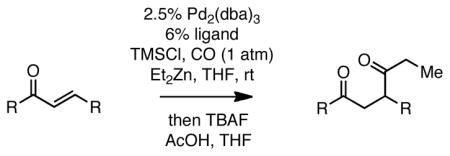

Table 2.

Carbonylative Conjugate Addition of Et2Zn To α,β-Unsaturated Ketones.a

| |||

|---|---|---|---|

| entry | substrate | % yield | |

| L=PPh3 | L=PCy3 | ||

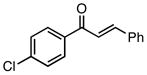

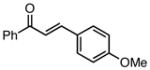

| 1 |  |

82 | 80 |

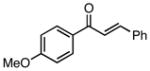

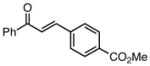

| 2 |  |

81 | 81 |

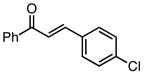

| 3 |  |

84 | 82 |

| 4 |  |

79 | 80 |

| 5 |  |

86 | 87 |

| 6 | 52 | 82 | |

| 7 | 67 | 66b | |

| 8 | 85 | 86 | |

| 9 | 56 | 48 | |

| 10 |  |

68 | 67 |

| 11 |  |

72 | 55c |

Reaction with 1.3 equiv Et2Zn, 2.3 equiv TMSCl, 1 atm CO, for 4 h (7 h for entry 4; 24 h for entry 11). Subsequent to reaction, the mixture was quenched at 0 °C with acetic acid (1.5 equiv) and TBAF (1.5 equiv) for 10 minutes and then treated with saturated Na2CO3.

Yield adjusted to account from unremovable impurity (ca. 10%).

10% Pd2(dba)3, 24% ligand, and 1.95 equiv Et2Zn employed.