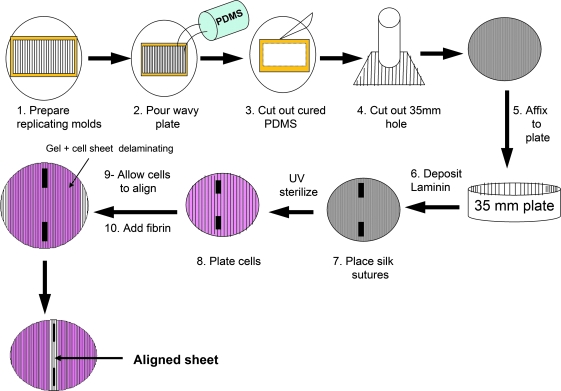

FIG. 1.

Process schematic for bioengineering rabbit longitudinal smooth muscle cell (RLSMC) sheet. Replicating molds with defined wavy surfaces were patterned with Epo-Tek using thermal expansion, oxidation, and UV curing. Poly(dimethylsiloxane) (PDMS)-based wavy culture plates were cured at room temperature for at least 2 days. Circles (35 mm) were cut out from the cured PDMS and secured with more PDMS in a standard 35 mm tissue dish. The plates were sterilized and prepped for culture. Laminin is deposited onto the plate, and silk sutures are pinned down. LSMCs were cultured separately and seeded onto the plate, and allowed to align along the axis of the waves on the plate. Once alignment was microscopically confirmed (approximately 4 days postcell seeding), a fibrin hydrogel was added to promote delamination and subsequent aligned construct formation. Once alignment was microscopically confirmed (approximately 4 days postcell seeding), a fibrin hydrogel was added to promote delamination and subsequent aligned construct formation.