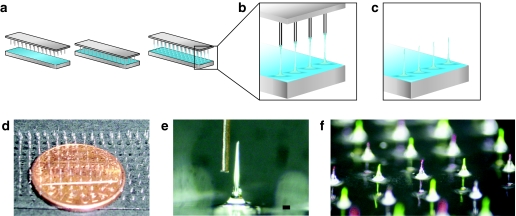

Figure 1.

Schematic of fabrication of protrusion array device (PAD) and example images. (a) Pin template and glass slide covered with a thin film of 20% polyvinyl alcohol (PVA) solution (left panel). The pin template is placed in contact with the PVA solution (middle panel). Microneedles are produced by withdrawing the pins as the film is drying, forming fiber-like structures (right panel). (b) Enlarged view of fibers. (c) Protrusions are subsequently trimmed to the desired length and tip shape. (d) PAD supported by a glass substrate, with a penny to show scale. (e) Micrograph of one microneedle after trimming to 1 mm length, showing beveled structure that facilitates skin penetration, with a human hair to show scale (bar = 80 µm). (f) PAD needles loaded alternately with fluorescein (green) and R-phycoerythrin (red).